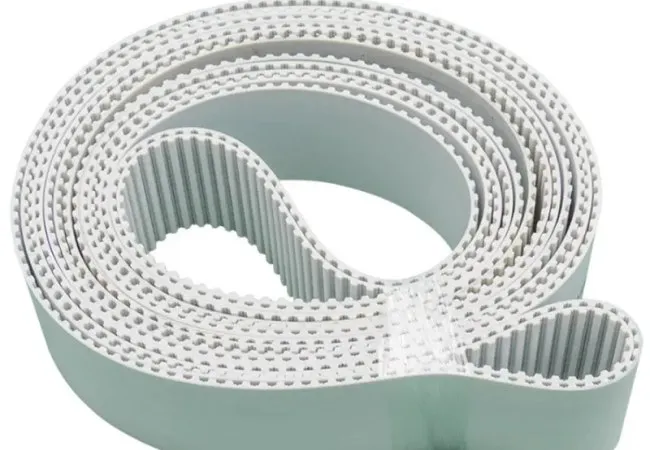

The Welded TPU Timing Belts and PU Timing Belts are polyurethane endless conveyor timing belts manufactured from standard open-ended belts. They are joined under heat on special machines. Our TPU Timing Belts and PU Timing Belts are mainly are used for conveying applications.

Open-ended belts with steel, aramid or stainless steel tensile fibers are prepared to the required size, where a "V"-shaped joint with fingers is cut at both ends, and after being inserted into a precise mold, is joined at a given temperature into an endless belt.

Types of Welded Timing Belt

- T Series (T5, T10 and T20)

- AT Series ( AT5, AT10 and AT20)

- HTD Series (5M, 8M and 14M)

- Imperial-Series ( XL, L, H, XH)

- Double Side Series (DT5, DAT5, DT10, DAT10, DT20, DAT20, D5M, D8M, D14M)

- Other Series

Welded TPU Timing Belts Characteristics

- High Transmitted Power and Long Service Life

- Resistant to Oil, Petrol, Benzene, UV Radiation and Ozone

- Abrasion Resistant

- Maintenance-free

- Temperature Range, Depending on Application, from −30 °C to +80 °C

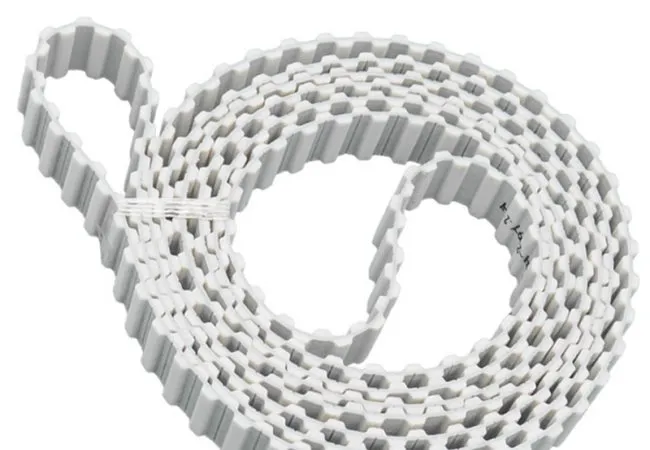

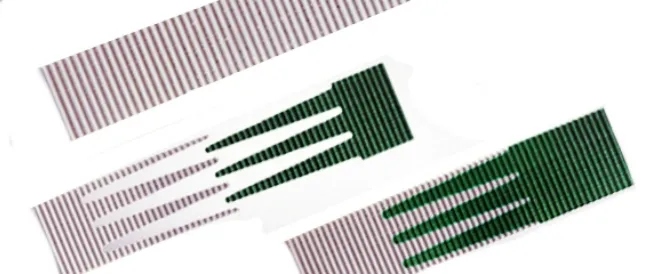

Welded Timing Belt Joins

Various surface layers and attachments can be welded or glued on the belts.

- Open-ended polyurethane belt

- Belt cut and ready for welding

Applications of Welded Timing Belt

Our Welded Polyurethane Timing Belts are used in wide range of industries as transporting belt in linear drives and positioning and lifting devices. You can apply our timing belts in industries like:

- Glass

- Ceramic

- Food

- Automotive

- Woodworking Industries.

Related Products

Inbelts is professional conveyor belts manufacturer in China. You can get all this types of bearing from our company.

Endless Timing Belt

Truly Endless TPU Timing Belts and PU Timing Belts are used for application of power transmission. It is seamless belt, which can drive machinery and convey heavy goods.

Welded Timing Belt

Welded & Spliced TPU Timing Belts and PU Timing Belts are belt end jointed together through heat welding process, which are mainly are used for conveying applications.

Open End Timing Belt

Open Ends TPU Timing Belts and PU Timing Belts are used for linear drive, it is high wear resistance and great running characteristics, and belts can be in any length.

Industries

Inbelts provides conveyor belts and belt conveyors for different industries like food process, tobacco, logistics, airport, printing, electronics, fitness equipment, wood process, stone and marble process, etc.