How to Choose a Powered Roller Conveyor?

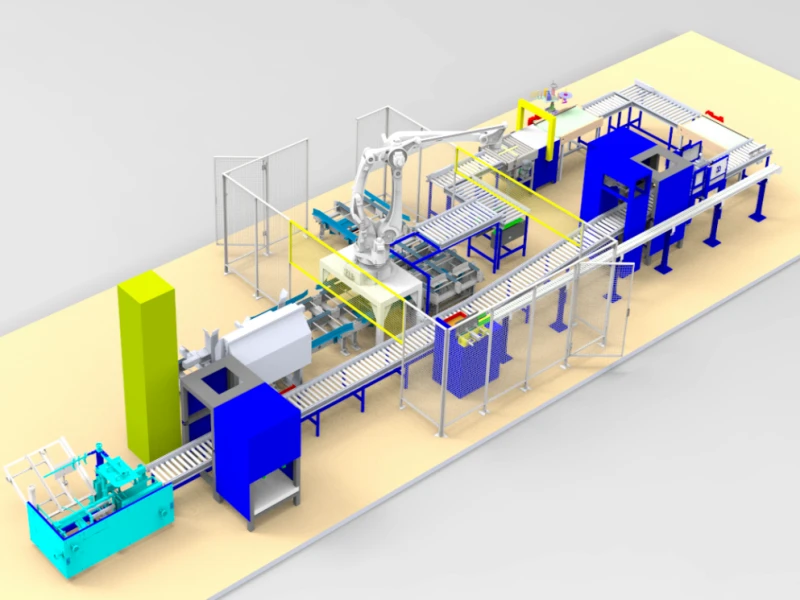

Choosing a powered roller conveyor involves evaluating your operational needs, material characteristics, facility layout, and budget to ensure efficient, reliable, and controlled material handling.

How to Choose a Unpowered Roller Conveyor?

Since unpowered roller conveyors rely on gravity or manual force to move items, they are simple, cost-effective solutions ideal for short-distance transport.

How to Choose a Gravity Roller Conveyor?

Gravity roller conveyors rely on a slight incline or manual force to move items, making them simple and energy-free but requiring careful selection for optimal performance.

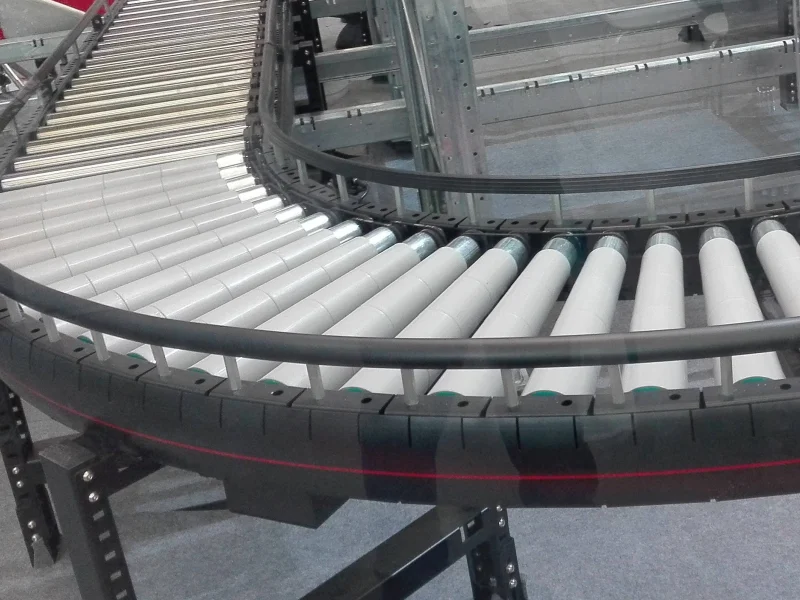

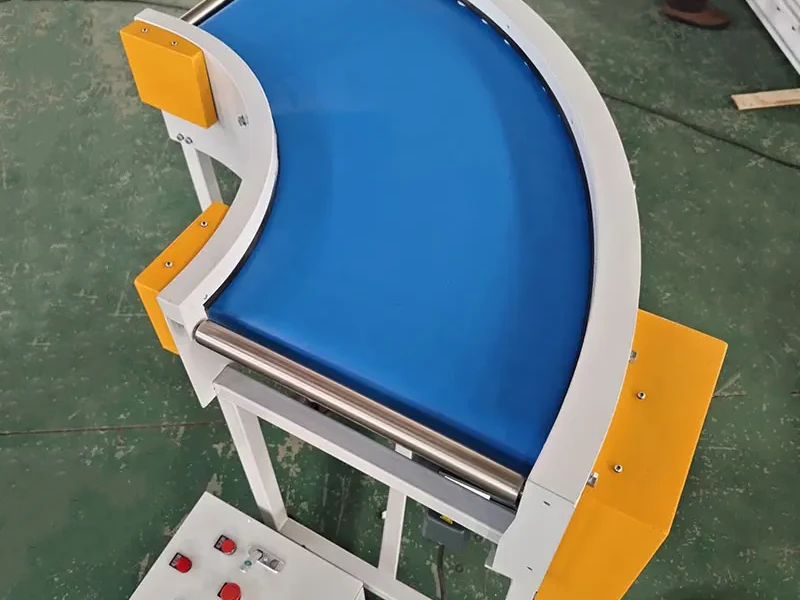

How to Choose a Curved Roller Conveyor?

A well-selected curved roller conveyor will ensure efficient material flow, fit your space, and meet performance requirements. Below is a step-by-step guide to help you make an informed decision.

Belt Conveyor Design Considerations for High and Low Temperature Environments

Proper design measures must be implemented to ensure reliable operation under varying temperature conditions.

Hygiene Requirements and Applications of Belt Conveyors in the Food Industry

This article provides an in-depth overview of hygiene standards and best practices for belt conveyors to ensure the highest level of hygiene in food processing.

Industrieal Conveyors in the Baking Industry

In modern bakeries, conveyor systems have become an essential tool, providing high efficiency and high-quality production solutions.

Telescopic Belt Conveyors Maintenance

Today, we will explore the safety and maintenance of telescopic belt conveyors, which are critical factors in ensuring efficient operation in industrial production.

Telescopic Belt Conveyor Working Principle

A telescopic belt conveyor consists of multiple sections (typically 2 to 5), here’s a more detailed and enriched version of your article on the Telescopic Belt Conveyor Working Principle.