Hygiene Requirements and Applications of Belt Conveyors in the Food Industry

Today, we will delve into the hygiene requirements and applications of belt conveyors in the food industry. The development of the food industry not only requires efficient production lines but also demands ensured product safety and hygiene. Belt conveyors play an indispensable role in achieving these objectives. This article provides an in-depth overview of hygiene standards and best practices for belt conveyors to ensure the highest level of hygiene in food processing.

1. Importance of Belt Conveyors in the Food Industry

Belt conveyors are one of the most common types of transportation equipment in the food industry. They are widely used to transport raw materials, finished products, or semi-finished products from one processing point to another. Their importance is reflected in the following aspects:

- Improved Production Efficiency: Belt conveyors allow for continuous transportation of food materials without interruptions, significantly enhancing production efficiency and reducing operational costs.

- Reduced Manual Intervention: Using belt conveyors minimizes manual handling, thereby reducing the risk of external contamination and ensuring product hygiene and safety.

- Consistency in Product Quality: Belt conveyors provide stable and consistent transportation, ensuring uniformity in the production process and enhancing product quality.

- Reduced Food Waste: Precise transportation helps reduce food loss during processing, saving costs and optimizing resource utilization.

Despite their vital role in the food industry, belt conveyors must meet strict hygiene standards to ensure the safety and cleanliness of the final products.

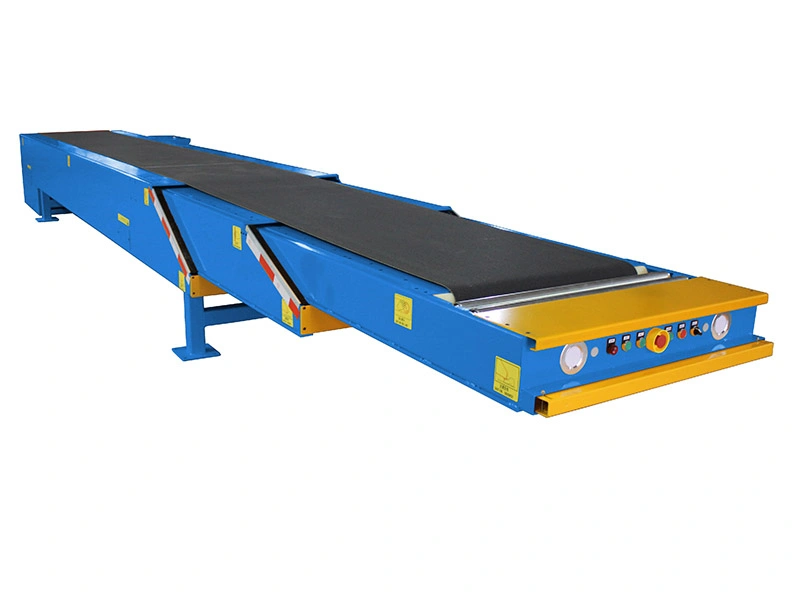

These are some belt conveyors for food industry.

2. Hygiene Requirements for Belt Conveyors

Hygiene is a critical concern in the food industry. Food safety and quality are under strict regulatory scrutiny, so belt conveyors must adhere to stringent hygiene standards. Here are key hygiene requirements and best practices:

Material Selection and Surface Treatment

- Choose materials that are safe for food contact, such as stainless steel, to reduce the risk of contamination and corrosion.

- Conveyor surfaces should be smooth and easy to clean, avoiding the accumulation of dirt and microorganisms.

Design and Structure

- Conveyor design should prioritize easy cleaning and maintenance.

- Avoid corners, gaps, and seams where dirt and bacteria can accumulate. All connection points should be smooth and seamless to prevent bacterial growth.

Cleaning and Disinfection

- Regular cleaning and disinfection of the conveyor system are essential to prevent contamination.

- Use food-grade cleaning agents and disinfectants and follow manufacturer-recommended cleaning procedures.

Preventing Cross-Contamination

- Ensure that different types of food or products at various processing stages do not cross-contaminate.

- Consider using multiple conveyor belts or implementing isolation measures where necessary.

Maintenance and Upkeep

- Regularly inspect and replace worn parts to ensure proper functioning and maintain hygiene standards.

- Establish a maintenance schedule to prevent mechanical failures that could compromise hygiene.

Employee Training

Train staff on hygiene protocols, including proper cleaning procedures and how to identify and report potential food safety risks.

Monitoring and Record-Keeping

- Implement a system to monitor and document the hygiene status of conveyors.

- Maintain detailed records to track sanitation practices and take corrective measures if issues are identified.

This is a telescopic belt conveyor for food industry.

3. Applications of Belt Conveyors in Various Food Industries

Belt conveyors have broad applications across different sectors of the food industry, including:

Candy Manufacturing

Used to transport candy from molding machines to packaging lines, ensuring product integrity and quality.

Bakery and Pastry Production

In bread and pastry production, conveyors transport dough or pastries from mixers to ovens, ensuring uniform baking.

Meat Processing

Conveyors are essential for transporting meat products like meat blocks and sausages, ensuring hygiene and enhancing production efficiency.

Vegetable and Fruit Processing

Used across multiple stages, from washing and cutting to packaging, ensuring the safety and cleanliness of produce.

Beverage Production

Conveyors transfer bottled or canned beverages from filling machines to packaging lines, enhancing efficiency.

In the food industry, belt conveyors are indispensable equipment that enhance production efficiency while ensuring product quality and safety. However, meeting hygiene standards requires appropriate design, regular maintenance, and thorough cleaning practices.

Only under these conditions can belt conveyors perform at their best, ensuring that hygiene and quality standards in the food industry are upheld. We hope this article has been helpful. If you have any questions or need further information, please feel free to contact us.

Leave Me Your Requirement!