How Will We Design a Telescopic Belt Conveyor for You?

Designing a telescopic belt conveyor involves careful consideration of various factors to ensure its efficiency, safety, and compatibility with specific applications. Here is a step-by-step guide to help you know how we design a telescopic belt conveyor for you.

Step 1: Define Requirements and Objectives

- Understand the Application

Clearly define the purpose of the telescopic belt conveyor. Determine whether it will be used for truck loading, container loading, or another application. - Specify Load Requirements

Define the types of products or materials the conveyor will handle, along with their dimensions, weight, and any special requirements. - Consider Space Constraints

Assess the available space for the telescopic conveyor, including the extended and retracted lengths, to ensure it fits within the designated area.

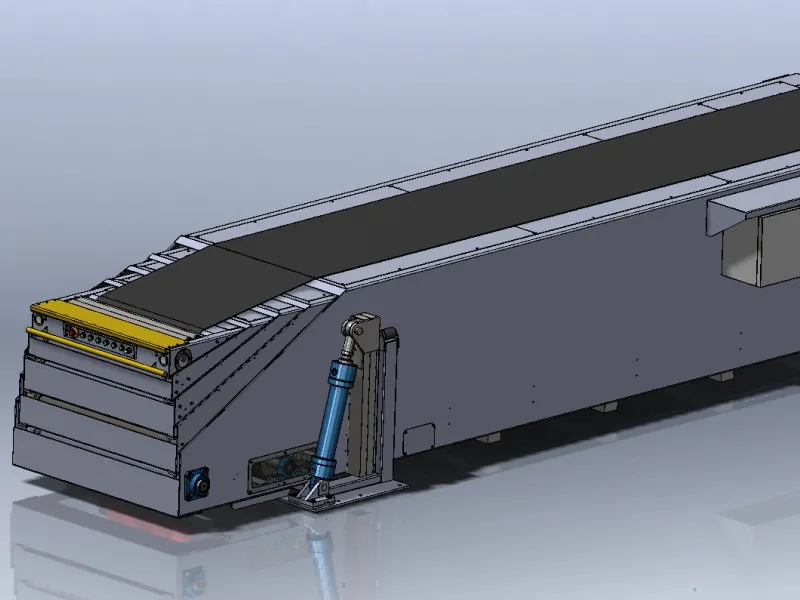

Step 2: Determine Conveyor Type

- Choose Telescopic Mechanism

Decide on the type of telescopic mechanism, whether it's a rack and pinion, hydraulic, or another system. Consider factors such as speed, precision, and ease of maintenance. - Select Belt Type

Choose the appropriate belt type based on the materials being transported. Consider factors such as grip, durability, and resistance to abrasion.

Step 3: Calculate Conveyor Dimensions

- Determine Extended and Retracted Lengths

Calculate the required extended and retracted lengths of the telescopic conveyor based on the application and space constraints. - Consider Height Adjustability

If the conveyor needs to accommodate different truck or container heights, design an adjustable height feature.

Step 4: Structural Design

- Select Frame Material

Choose materials for the conveyor frame based on factors such as load capacity, durability, and environmental conditions. - Consider Safety Features

Integrate safety features such as emergency stops, guards, and sensors to enhance operator safety.

Step 5: Power and Control Systems

- Choose Drive System

Select an appropriate drive system, whether it's electric, hydraulic, or pneumatic, based on the application's requirements. - Implement Control System

Design a control system that allows for precise control of the telescopic conveyor, including speed, direction, and height adjustments.

Step 6: Consideration for Accessories

Integrate Accessories: Depending on the application, consider integrating accessories such as side guides, photoelectric sensors, and weighing systems.

Step 7: Compliance with Standards

Ensure Compliance: Ensure that the telescopic belt conveyor design complies with relevant safety and industry standards.

Step 8: Prototype and Testing

- Build a Prototype

Construct a prototype based on the design specifications. - Conduct Testing

Test the telescopic conveyor under various conditions to ensure its performance, reliability, and safety.

Step 9: Documentation

Create Documentation: Document the design specifications, including drawings, manuals, and maintenance procedures.

Step 10: Installation and Training

- Installation

Ensure proper installation of the telescopic conveyor, considering factors such as alignment and stability. - Training

Provide training to operators and maintenance personnel on how to use and maintain the telescopic conveyor.

Keep in mind that the design process may require collaboration with engineers, manufacturers, and other stakeholders to ensure a successful outcome. Regular maintenance and periodic inspections are crucial to extending the life of the telescopic belt conveyor and ensuring its ongoing performance.

Leave Me Your Requirement!