Industrieal Conveyors in the Baking Industry

The baking industry has always been a prominent sector in the food industry, not only because of its delicious products but also due to its precise production processes. In modern bakeries, conveyor systems have become an essential tool, providing high efficiency and high-quality production solutions. This article explores the applications of conveyors in the baking industry, showcasing their key role in lean baking processes.

1. Introduction to Conveyors

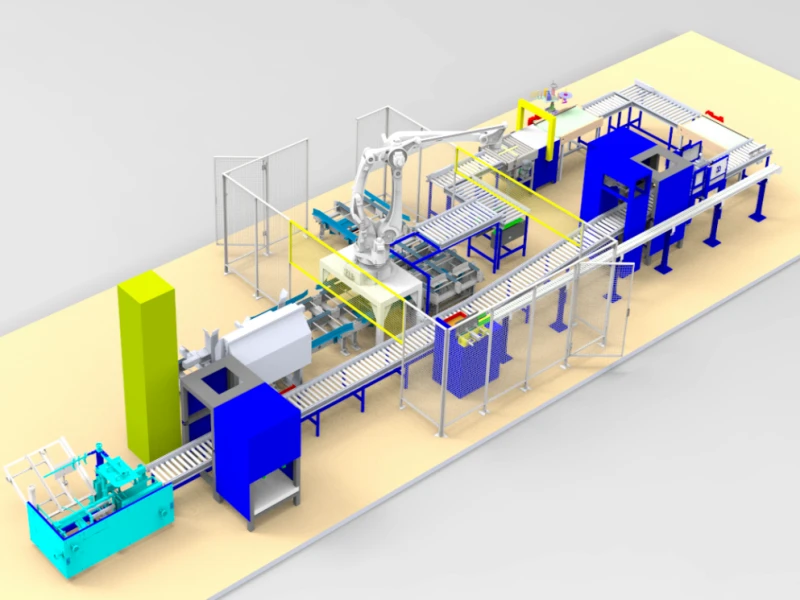

A conveyor is a mechanical device used for material transportation, capable of automatically conveying various materials such as flour, dough, sugar, and cream. Conveyor systems typically consist of belt conveyors or chain conveyors or roller conveyor driven by transmission devices, allowing materials to move along a predetermined path. In the baking industry, conveyors are widely used in the following areas:

1.1 Raw Material Supply

In the baking process, the preparation of raw materials is crucial. Conveyors can transport raw materials from storage areas to mixing and preparation zones, reducing manual handling and improving production efficiency.

1.2 Dough Preparation

For baked goods such as bread and cakes, conveyors transport dough from mixers to dividers or molding machines. This ensures even and consistent dough handling, maintaining process uniformity.

1.3 Baking Process

Conveyors are used inside ovens to transport dough or semi-finished products to the correct baking position. They allow precise control over conveying speed and baking time, ensuring even heating and preventing uneven baking.

1.4 Cooling and Packaging

After baking, products go through cooling, packaging, and labeling processes. Conveyor systems help automate these steps, enhancing production line efficiency while minimizing manual intervention.

2. Advantages of Conveyors in Lean Baking Processes

In the baking industry, conveyor systems offer multiple advantages, making them essential for improving efficiency and quality.

2.1 Efficient Production Process

Conveyor systems enable continuous transportation without pauses, ensuring the seamless operation of baking production lines. They can adapt to different materials and process requirements, ensuring smooth production.

2.2 Improved Consistency

The quality and texture of baked products depend on process consistency. Conveyor systems help maintain uniform material distribution and handling, leading to higher product quality and consistency.

2.3 Reduced Human Errors

Manual operations are prone to human errors, whereas conveyor systems minimize manual intervention, reducing error rates during production. This is especially important for highly precise baking processes.

2.4 Reduced Labor Costs

By automating heavy manual tasks, conveyor systems lower labor costs and improve production efficiency. This is particularly beneficial for large-scale bakeries.

3. Application Cases of Conveyors in the Baking Industry

3.1 Bread Production

In bread-making, conveyor systems transport mixed dough to forming machines, ovens, and packaging areas. This automated process ensures high product quality and uniformity.

3.2 Biscuit Manufacturing

In biscuit production, conveyors transfer biscuits from ovens to cooling racks and finally to packaging areas. This automation increases efficiency and reduces manual intervention.

3.3 Cake Production

For cake production, conveyor systems transport cake molds from molding stations to ovens, ensuring even baking and consistent quality.

Conveyor systems have become an indispensable tool in the baking industry. They play a crucial role in lean baking processes, improving efficiency, ensuring product quality, and providing a solid foundation for the success of bakeries.

As technology advances, conveyor systems will continue to evolve, offering new opportunities and challenges for the baking industry. We hope these application cases inspire more bakeries to leverage the advantages of conveyor systems and achieve higher efficiency and superior product quality.

Leave Me Your Requirement!