Seamless Belts

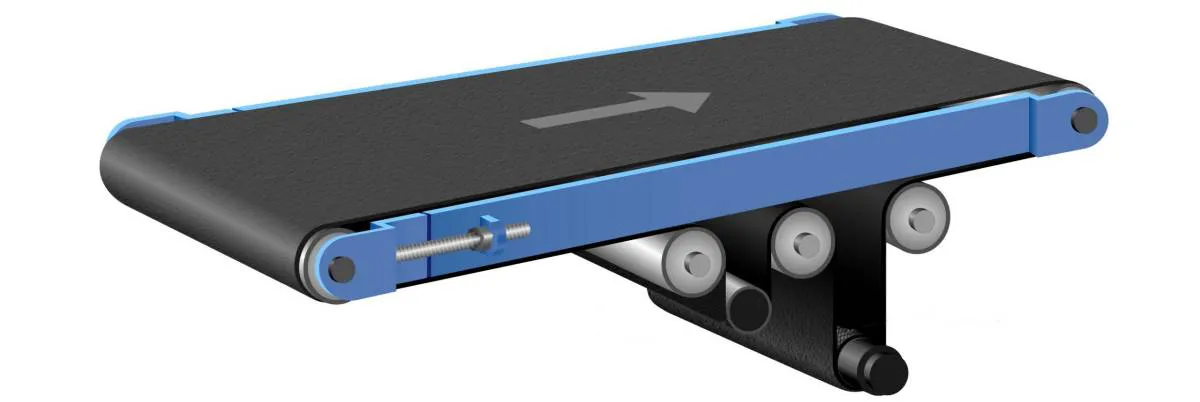

Seamless Conveyor Belts

Seamless Conveyor Belts

Seamless conveyor belts are continuous belts manufactured without a joint or seam, providing a completely smooth and uniform surface. These belts are ideal for applications requiring precise movement, consistent performance, and minimal risk of contamination. Their seamless design eliminates weak points, ensuring durability and longevity under various operating conditions. The seamless conveyor belt is a truly seamless woven (using endless woven) belt. Through our strict quality control, the consistency of belt size and tolerance is maintained.

The Types of Seamless Belt

The substrate of seamless conveyor belt is manufactured endless on looms or knitted as a tube. Inbelts seamless conveyor belts come in various types, each designed to meet specific industrial needs:.

- Power Transmission Belts

The seamless transmission belts can be used in light duty applications, including lathes, grinders, vacuum cleaners, and spindle drives. The strength are based on different fabric designs. - Surface Coated Conveyor Belts

The surface coated seamless conveyor belts are able to transport light objects. The surface of the coated conveyor belts can be different materials.

The Types of Endless Woven

The base fabric of a seamless conveyor belt plays a crucial role in its strength, flexibility, and operational efficiency. Common fabrics include:

- Polyester Fabric: Offers excellent resistance to stretching and provides stability in high-speed operations.

- Nylon Fabric: Known for its high tensile strength and superior impact resistance.

- Cotton Fabric: Used in lightweight applications where flexibility and breathability are required.

- Kevlar Fabric: Ideal for high-temperature and heavy-duty applications due to its exceptional heat and wear resistance.

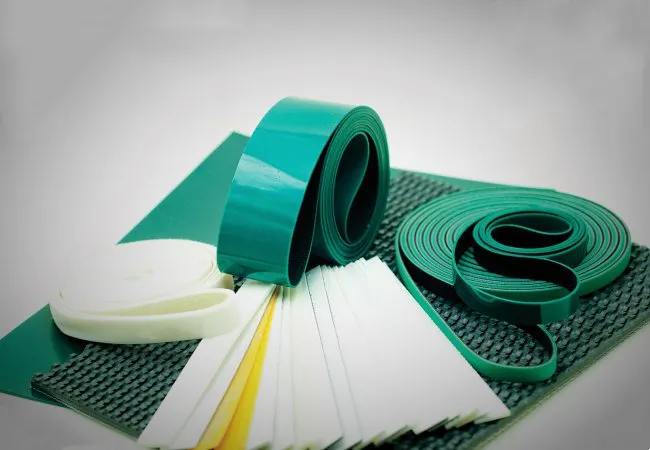

The Surface of Seamless Belt

The surface of true endless woven belts are manufactured based on individual applications requirements. The fabric layer is then coated with TPU, PVC, or silicone, depending on the application requirements.

You can get all these seamless conveyor belts.

- Rubber Seamless Belts: Made from high-quality rubber materials, these belts provide excellent flexibility and durability.

- PU (Polyurethane) Seamless Belts: These belts are widely used in food processing and pharmaceutical industries due to their high resistance to oils, chemicals, and hygiene-friendly properties.

- Silicone Seamless Belts: Known for their high-temperature resistance and non-stick surface, ideal for baking and textile applications.

- Fabric Seamless Belts: Often used in applications requiring lightweight yet durable solutions.

- Teflon-Coated Seamless Belts: Provide high resistance to extreme temperatures and chemical exposure, commonly used in industrial drying processes.

You can get seamless conveyor belts with different surface features from Inbelts.

- Smooth Surface: Ensures precise product placement and is easy to clean.

- Rough Top Surface: Provides additional grip for inclines and declines in material handling.

- Anti-Static Coating: Prevents dust accumulation and reduces electrostatic discharge.

- Flame-Resistant Coating: Used in industries where fire safety is a concern, such as mining and chemical processing.

- Oil-Resistant Coating: Essential for industries dealing with oily or greasy materials.

The different surface coated materials are chosen according to your requirement. We can provide the right seamless conveyor belts for your projects.

Comparison: Seamless Belts vs. Traditional Conveyor Belts

Seamless conveyor belts offer several advantages over conventional conveyor belts with joints:

| Feature | Seamless Conveyor Belts | Traditional Conveyor Belts |

| Durability | Higher durability due to no weak points | Prone to wear and tear at joint areas |

| Precision | Provides smooth and vibration-free operation | May cause uneven movement due to joints |

| Maintenance | Requires less maintenance | Needs frequent maintenance and repair |

| Flexibility | More flexible and adaptable | Limited flexibility due to seams |

| Lifespan | Longer lifespan | Shorter lifespan due to seam failures |

Why to Choose Seamless Belts

Joint-free Design:

- No seams or joints, eliminating weak points that could lead to failure.

- Provides uniform tension distribution across the belt.

Smooth Surface:

- Ensures seamless contact with conveyed materials, reducing the risk of damage or contamination.

- Ideal for precision applications.

High Durability:

- Manufactured from high-quality materials like rubber, polyurethane, or silicone for excellent wear and tear resistance.

- Resistant to cracking, tearing, and delamination.

High Flexibility:

- Suitable for high-speed operations and small pulley diameters.

- Maintains flexibility and performance over time.

Applications of Seamless Belts

High-performance flat belts have experienced remarkable developments in response to demand for their use. Seamless belts are custom-engineered products for specific application needs.

The seamless belts can be used in industries like:

- Textile

- Banking

- Materials Handling

- Office Equipment

- Imaging

- Postal

- Fiber Optics

The seamless belts can be used in handling objects:

- Power Transmission

- Document Transport

- PC Board Conveyor

- Light Weight Tube Winders

- High Speed Power Transmission

- Currency Transport

- Drum Drive

- Yarn Twister

- Spinning Frame

Seamless conveyor belts provide a superior alternative to conventional belts, offering higher durability, precision, and low maintenance. Their diverse material compositions and coatings make them suitable for various industries requiring high performance and reliability. Investing in seamless belts enhances operational efficiency, reduces downtime, and extends equipment lifespan, making them a preferred choice in many industrial applications. Would you like assistance in selecting a seamless conveyor belt, determining suitable materials for your application, or sourcing a reliable supplier?