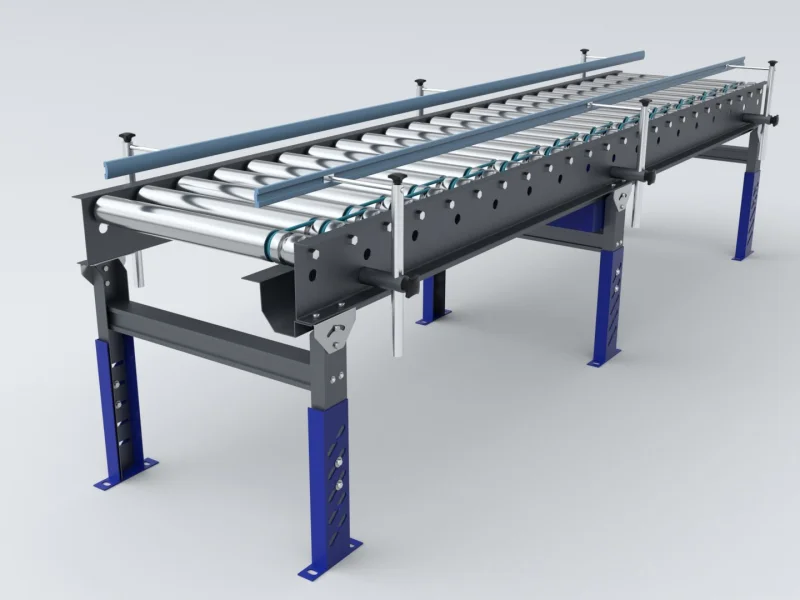

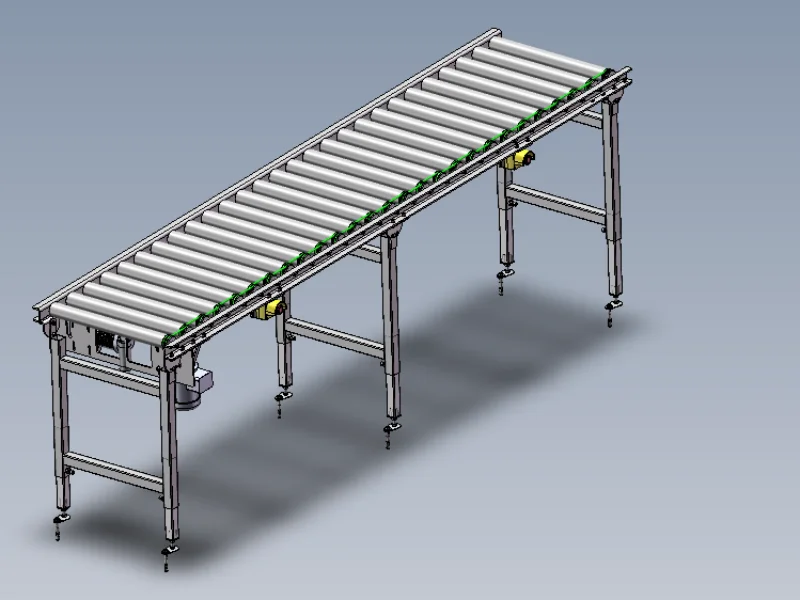

Roller Conveyor Spare Parts for Replacement

Roller conveyor spare parts are critical for maintaining conveyor functionality, minimizing downtime, and extending system life. Below is a comprehensive guide on spare parts for roller conveyors (gravity, powered, chain-driven, accumulation, pallet, etc.), including types, specifications, etc.

Key Spare Parts for Roller Conveyors

Roller conveyors, whether gravity-fed or powered (e.g., chain-driven, motorized), rely on several components that may wear out or require replacement. Here's a list of the most common roller conveyor spare parts, their functions, and considerations:

1. Rollers

Function: Support and move loads; rotate to transport items along the conveyor.

Types:

- Gravity Rollers: Non-driven, steel, plastic, or aluminum (1.5"–3.5" diameter). Using a gravity roller conveyor is an economical way of conveying.

- Powered Rollers: Driven by chains, belts, or internal motors (e.g., 24V DC motorized). Although the use of a powered roller conveyor increases costs, the control is more efficient and their use is more widespread.

- Tapered Rollers: For curved conveyors, wider at outer edge. The use of a curved roller conveyor can change the direction of material conveying and save floor space.

Specifications:

- Diameter: 1.5"–1.9" (light-duty), 2.5"–3.5" (heavy-duty).

- Length: Matches conveyor width (e.g., 12"–54").

- Material: Steel (galvanized), stainless steel (food-grade), plastic (light loads).

- Bearings: Non-precision (gravity) or precision (powered/heavy-duty).

- When to Replace: Worn bearings, bent rollers, or surface damage (e.g., dents, corrosion).

2. Roller Chains

Function: Transmit power in chain-driven conveyors from motor to rollers or between rollers.

Types:

- ANSI-standard (#40, #50, #60): Carbon steel, stainless steel, or nickel-plated.

- Heavy-duty (#60H) or double-pitch (C2050) for specific applications.

Specifications:

- Pitch: #40 (1/2"), #50 (5/8"), #60 (3/4").

- Tensile Strength: #40 (3,700 lbs), #50 (6,100 lbs), #60 (8,500 lbs).

- Length: 10' sections or 100' rolls; custom-cut for conveyor loop.

- When to Replace: Elongation (>3%), broken links, or excessive wear.

3. Sprockets

Function: Engage the chain to drive rollers or connect to the motor shaft.

Types:

- Roller sprockets: Attached to roller axles.

- Drive sprockets: On motor or gearbox shaft.

Specifications:

- Chain compatibility: #40, #50, #60.

- Teeth: 10–30 (15–20 common for conveyors).

- Bore: 1/2"–1" (matches roller axle or shaft).

- Material: Steel, stainless steel.

- When to Replace: Worn or broken teeth, misalignment.

4. Bearings

Function: Allow rollers to rotate smoothly within the frame.

Types:

- Non-precision: Basic, for gravity or light-duty.

- Precision: Sealed or shielded, for powered/heavy-duty.

- Flanged or press-fit: Match roller axle (e.g., 7/16" hex).

Specifications:

- Bore: 1/4"–1" (common: 7/16" hex for conveyor rollers).

- Load rating: 50–500 lbs per bearing.

- When to Replace: Noisy, seized, or reduced rotation.

5. Drive Components (Powered Conveyors)

Motors:

- Function: Power the chain or rollers (e.g., 1/2–5 HP, 110V–480V).

- Types: AC (standard), DC (24V for motorized rollers).

Gearboxes:

- Function: Reduce motor speed, increase torque.

Drive Belts/Bands:

- Function: Connect line-shaft to rollers (less common in chain-driven).

- When to Replace: Motor failure, gear wear, or belt stretching.

6. Frame Components

- Side Rails: Steel or aluminum channels holding rollers.

- Supports/Legs: Adjustable or fixed stands.

- Cross-Braces: Reinforce frame stability.

- When to Replace: Bent, rusted, or damaged from impact.

7. Accessories

- Side Guides/Rails: Prevent loads from falling (2"–6" high).

- End Stops: Stop items at conveyor end (gravity systems).

- Chain Guards: Cover chains for safety.

- Sensors: For accumulation or control (powered systems).

Selection Criteria for Roller Conveyor Spare Parts

1. Match Conveyor Specifications

- Confirm roller diameter, chain pitch (#40, #50, #60), and frame width from your conveyor's manual or supplier.

- Example: A 24" wide conveyor with 1.9" rollers and #50 chain needs matching parts.

2. Load and Application

- Light-Duty (<200 lbs): #40 chain, 1.9" steel rollers, non-precision bearings.

- Medium-Duty (200–1,000 lbs): #50 chain, 2.5" rollers, precision bearings.

- Heavy-Duty (1,000–5,000 lbs): #60 chain, 3.5" rollers, heavy-duty bearings.

3. Environment

- Dry/Indoor: Carbon steel rollers/chains.

- Washdown/Food-Grade: Stainless steel rollers/chains, sealed bearings.

- Corrosive/Outdoor: Nickel-plated chains, galvanized rollers.

4. Compatibility

- Ensure sprockets match chain pitch and roller axles (e.g., 7/16" hex).

- Verify motor voltage (e.g., 110V, 480V) and control system for powered parts.

5. Maintenance Frequency

- Stock high-wear parts (chains, rollers, bearings) for quick replacement.

- Example: Keep 20' of #50 chain and 10 rollers for a 10' conveyor.

Maintenance and Replacement Tips

Stock Critical Parts: Keep rollers, chains, sprockets, and bearings on hand (e.g., 10 rollers, 20' chain for a 10' conveyor).

Inspect Regularly

- Rollers: Check for bent axles or worn bearings monthly.

- Chains: Lubricate every 100–500 hours; replace if stretched >3%.

- Sprockets: Inspect teeth for wear quarterly.

- Tool Kit: Hex wrenches, chain breakers, and lubrication tools for quick repairs.

- Downtime Plan: Replace parts during scheduled maintenance to avoid production halts.

Example Roller Conveyor Spare Parts List

Scenario

10' chain-driven roller conveyor for 1,000-lb pallets (48" x 40").

Conveyor Specs

54" wide, 2.5" steel rollers, 4" spacing, #50 chain, chain-driven, 2 HP motor.

Spare Parts Needed

- Rollers: 5 × 2.5" steel (54" long) = $50–$100.

- Chain: 20' of #50 carbon steel = $20–$50.

- Sprockets: 5 × #50, 15-tooth = $50–$100.

- Bearings: 10 × precision (7/16" hex) = $50–$100.

- Side Guides: 10' × 4" high = $50–$100.

- Total Cost: ~$220–$450.

Roller conveyor spare parts include rollers, chains, sprockets, bearings, and drive components. Selection depends on load, environment, and conveyor specs. Stock high-wear parts and source from Grainger, Tsubaki, or Made-in-China.com for cost-effective replacements. If you need a specific part list, pricing for a particular conveyor, or supplier recommendations, share your conveyor details (e.g., type, load, size), and I'll refine the response!

Leave Me Your Requirement!