Powered roller conveyors are a robust, flexible solution for modern material handling, excelling in environments where control, capacity, and automation are priorities. Inbelts is an powered roller conveyors manufacturer in China. If you'd like details on specific drive types, cost estimates, or comparisons with other conveyors, let me know!

About Powered Roller Conveyor

A powered roller conveyor is a type of roller conveyor that uses an external power source, typically an electric motor, to drive the rollers and move items along the system. Unlike gravity or unpowered roller conveyors, it provides precise control over speed, direction, and movement, making it ideal for automated and heavy-duty applications. Below is a detailed overview of its design, features, advantages, disadvantages, and applications.

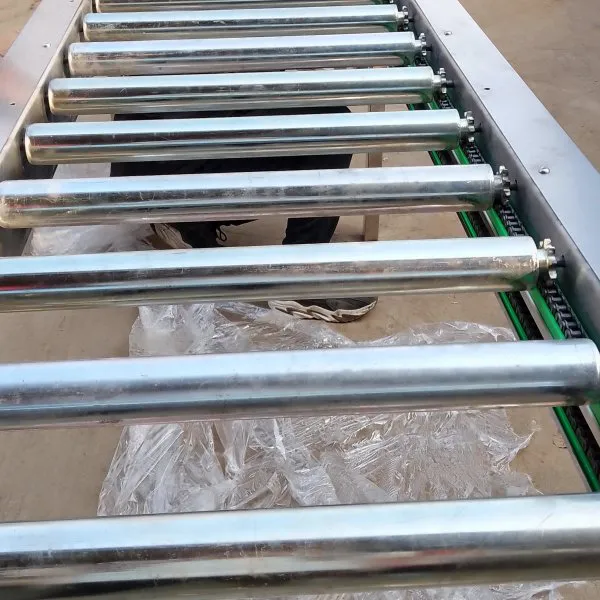

Conveyor Rollers

- Made from durable materials like steel, aluminum, or plastic, depending on load requirements. Steel rollers handle heavy items, while plastic suits lighter or delicate goods.

- Some rollers are powered directly (e.g., via internal motors), while others are driven by belts, chains, or shafts.

Drive Mechanism

- Motorized Rollers: Individual rollers may contain built-in motors (e.g., 24V DC motorized drive rollers) for precise control.

- Belt or Chain Drive: A motor drives a belt or chain that connects multiple rollers, turning them in unison.

- Line Shaft: A single shaft runs beneath the rollers, powered by a motor, with bands or belts linking it to each roller.

Conveyor Frame

- Constructed from steel or aluminum for strength, supporting the rollers and the weight of the load. Can be straight, curved, or inclined.

Control Systems

- Equipped with sensors, programmable logic controllers (PLCs), or variable frequency drives (VFDs) to regulate speed, start/stop functions, and accumulation zones.

Roller Spacing

- Adjustable spacing ensures smooth transport of items, tailored to their size and stability to prevent tipping or jamming.

Safety Features

- Includes emergency stop buttons, guards, or sensors to detect jams and halt operation, protecting workers and goods.

Accumulation Capability

- Some designs feature zones where items can stop and accumulate without pressure (zero-pressure accumulation), ideal for buffering or sorting.

Modularity

- Sections can be added, reconfigured, or combined with curves and merges to suit complex layouts.

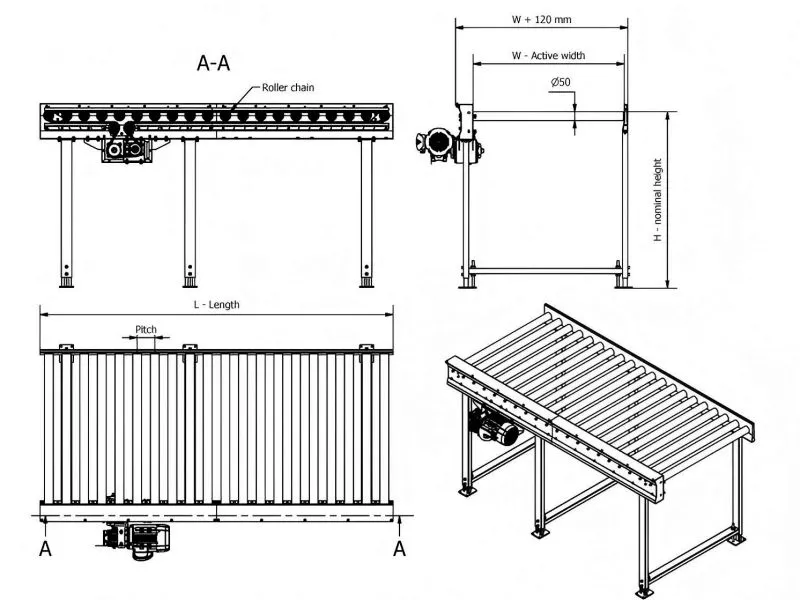

Drawings and Layout

This picture is simple layout of powered roller conveyor layout (we can provide curved powered roller conveyor and straight powered roller conveyor).

Product Details

Advantages of Powered Roller Conveyor

- Precise Control: Motorized operation allows adjustable speed, direction, and stopping, enhancing automation and workflow efficiency.

- High Load Capacity: Capable of handling heavy or bulky items, such as pallets or machinery parts, over long distances.

- Versatility: Works with a wide range of item types and can navigate inclines, declines, or flat surfaces without relying on gravity.

- Continuous Operation: Suitable for high-volume, 24/7 environments where consistent movement is critical.

- Automation Integration: Easily connects with sensors, robotics, and other systems for fully automated material handling.

- Reduced Manual Effort: Eliminates the need for pushing or repositioning items, lowering labor costs and injury risks.

Applications of Powered Roller Conveyor

- Warehousing and Distribution: Moves packages, pallets, or totes across large facilities, often integrated with sorting or picking systems.

- Manufacturing and Assembly Lines: Transports heavy components (e.g., engines, appliances) between production stages, supporting automated workflows.

- E-commerce Fulfillment Centers: Handles high volumes of orders, directing packages to packing or shipping zones with precision and speed.

- Airport Baggage Handling: Powers luggage movement through terminals, ensuring consistent flow from check-in to aircraft loading.

- Food and Beverage Processing: Moves crates, cans, or bottles in hygienic designs (e.g., stainless steel rollers) that meet industry standards.

- Automotive Industry: Transports large parts or assembled vehicles through production and inspection lines, leveraging high load capacity.

- Pharmaceutical Manufacturing: Delivers sensitive products like vials or boxes with controlled speed and minimal disruption.

Powered Roller Conveyor Data Sheet

| Category | Specification |

| Type | Powered (Belt-Driven, Chain-Driven, or Motorized Drive Rollers - MDR) |

| Application | Material handling in warehouses, distribution centers, manufacturing, assembly lines |

| Load Capacity | Up to 500 kg (1100 lbs) per linear meter |

| Conveyor Width | 300 mm to 1200 mm (customizable) |

| Roller Diameter | 50 mm, 60 mm, or 89 mm (standard) |

| Roller Material | Steel, stainless steel, or PVC-coated |

| Frame Material | Powder-coated steel or stainless steel |

| Roller Pitch | 75 mm to 150 mm (depending on load requirements) |

| Roller Type | Straight or tapered rollers (for curved sections) |

| Drive Type | Belt-Driven, Chain-Driven, or Motorized Drive Rollers (MDR) |

| Motor Power | 0.5 kW to 2.2 kW (depending on load and speed requirements) |

| Voltage | 230V/415V, 50/60 Hz (or as per regional standards) |

| Speed | Adjustable: 10-30 m/min (standard) |

| Control System | Variable frequency drive (VFD) for speed control |

| Overall Length | Customizable (e.g., 2 m to 10 m) |

| Height | Adjustable legs (standard range: 700 mm to 1200 mm) |

| Operating Temperature | -20°C to 60°C (-4°F to 140°F) |

| Humidity | Up to 95% (non-condensing) |

| Dust/Water Resistance | IP54 or IP65 (optional) |

| Safety Features | Emergency stop buttons, side guards, roller covers, load sensors |

| Maintenance | Self-lubricating bearings, periodic greasing, easy-to-clean design |

| Optional Features | Accumulation zones, sorting systems, IoT integration, custom coatings |

| Standards | ISO 9001, CE, OSHA, ANSI |

| Certifications | RoHS, REACH (for environmental compliance) |

| Lead Time | 4-6 weeks (standard), 8-10 weeks (custom) |

| Warranty | 12 months (standard), extendable |

| Packaging | Wooden crates or pallets for safe shipping |

Related Products

Inbelts is professional portable flexible powered roller conveyors manufacturer in China. You can get all this types of flexible powered roller conveyors for goods transferring in plant like warehouse..

Pallet Roller Conveyor

A pallet roller conveyor is a heavy-duty roller conveyor specifically designed to transport pallets—flat structures used to carry goods—across various industrial settings.

Accumulation Roller Conveyor

An accumulation roller conveyor is a specialized type of roller conveyor designed to allow items to stop and accumulate at specific points along the roller conveyor system.

Powered Roller Conveyor

A powered roller conveyor is a type of roller conveyor that uses an external power source, typically an electric motor, to drive the rollers and move items along the system.

Industries

Roller conveyors play a critical role in industries that require efficient, reliable, and often heavy-duty material handling. From warehouses and manufacturing plants to airports and retail backrooms, their versatility and adaptability make them indispensable for streamlining operations and improving productivity.

- Post

- Home Appliances

- Food

- Tobacco

- Light Industries

- E-Commerce

- Retail Stores

- Manufacturing & Packaging