Pallet roller conveyors are a powerful solution for heavy-duty material handling, excelling in environments where pallets are the primary unit of transport. Inbelts is a pallet roller conveyors manufacturer in China. If you'd like more specifics on load ratings, drive types, or integration options, let me know!

About Pallet Roller Conveyor

A pallet roller conveyor is a heavy-duty roller conveyor specifically designed to transport pallets—flat structures used to carry goods—across various industrial settings. These conveyors are built to handle significant weight and provide efficient movement of palletized loads, making them a staple in warehouses, manufacturing plants, and distribution centers. Below is a detailed overview of its design, features, advantages, disadvantages, and applications.

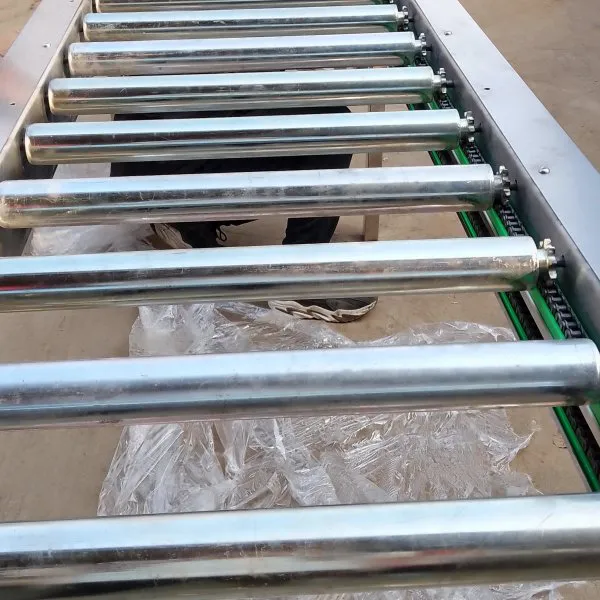

Conveyor Rollers

- Constructed from robust materials like steel to support heavy pallet loads (often 500–5,000 lbs or more).

- Rollers are typically wider and larger in diameter than those in standard conveyors to ensure stability and durability.

Conveyor Frame

- Made from heavy-gauge steel or reinforced aluminum to withstand substantial weight and maintain structural integrity.

- Can be straight, curved, or inclined, depending on the layout.

Drive Mechanism

- Powered: Most pallet roller conveyors use electric motors to drive rollers via chains, belts, or line shafts, ensuring consistent movement of heavy loads.

- Gravity-Fed: Some systems use a slight incline for lighter pallets or shorter distances, though this is less common due to weight considerations.

Roller Spacing

- Spaced to match standard pallet dimensions (e.g., 40" x 48" in North America), ensuring even support and preventing pallets from sagging or tipping.

- Typically closer together than in lighter-duty conveyors to handle the weight distribution.

Load Capacity

- Designed for high-capacity loads, often rated in tons, with reinforced rollers and frames to accommodate stacked or oversized pallets.

Control Systems

- Powered versions include sensors, programmable logic controllers (PLCs), or variable speed drives for precise movement, accumulation, or stopping.

Safety Features

- Equipped with side guards, emergency stops, and load sensors to prevent pallet derailment or operator injury.

- Some include pallet alignment guides to ensure proper positioning.

Specialized Options

- Accumulation Zones: Allows pallets to queue without pressure (e.g., zero-pressure accumulation).

- Turntables or Transfers: Enables directional changes or transfers to other lines.

- Low-Profile Design: For integration with forklifts or automated guided vehicles (AGVs).

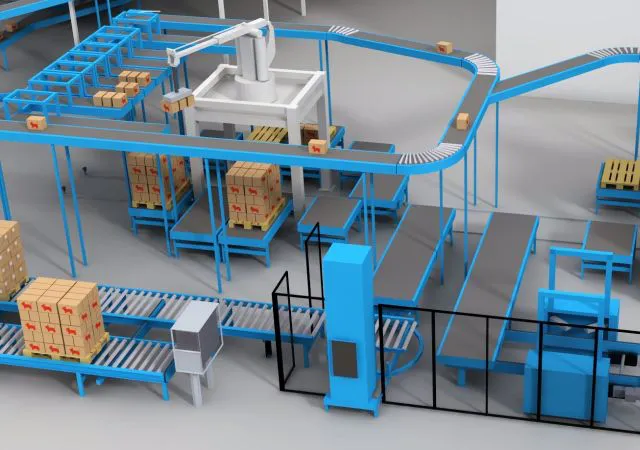

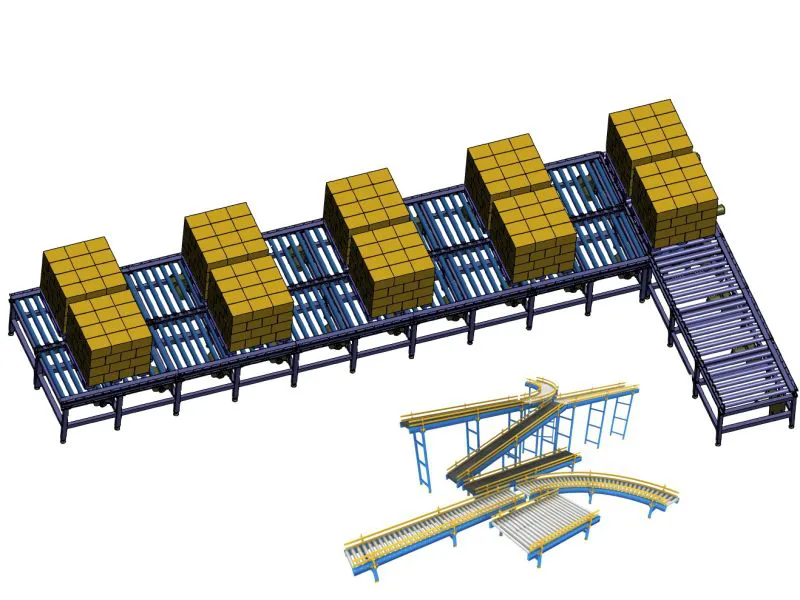

Drawings and Layout

This picture is simple layout of pallet roller conveyor layout.

Product Details

Advantages of Pallet Roller Conveyor

- High Load Capacity: Built to move heavy pallets efficiently, ideal for industrial-scale operations.

- Durability: Robust construction ensures long-term reliability under demanding conditions.

- Automation Compatibility: Easily integrates with warehouse management systems, AGVs, or robotic palletizers for streamlined workflows.

- Reduced Manual Handling: Minimizes the need for forklifts or manual labor, improving safety and efficiency.

- Customizable: Available in various lengths, widths, and configurations to suit specific pallet sizes and facility layouts.

- Consistent Movement: Powered systems provide reliable speed and control, even with heavy or uneven loads.

Applications of Pallet Roller Conveyor

- Warehousing and Distribution: Moves pallets of goods from receiving docks to storage racks or shipping areas, often integrated with automated storage and retrieval systems (AS/RS).

- Manufacturing: Transports palletized raw materials, components, or finished products between production stages (e.g., from assembly to packaging).

- E-commerce and Logistics: Handles large shipments on pallets, directing them to sorting, packing, or loading zones in fulfillment centers.

- Food and Beverage Industry: Moves pallets of packaged goods (e.g., crates, cases) in hygienic designs, often with stainless steel components for washdown environments.

- Automotive Industry: Transports heavy palletized parts (e.g., engines, transmissions) through assembly or storage processes.

- Retail Supply Chains: Facilitates pallet movement in distribution centers supplying stores, streamlining inventory replenishment.

- Cold Storage: Used in refrigerated warehouses with corrosion-resistant materials to move palletized perishable goods.

Pallet Roller Conveyor Data Sheet

| Category | Specification |

| Model Number | PR-120-300 |

| Type | Powered (Chain-Driven, Belt-Driven, or Motorized Drive Rollers - MDR) |

| Application | Heavy-duty material handling for pallets in warehouses, manufacturing, and distribution centers |

| Load Capacity | Up to 2000 kg (4400 lbs) per linear meter |

| Conveyor Width | 600 mm to 1500 mm (customizable) |

| Roller Diameter | 89 mm, 100 mm, or 150 mm (standard) |

| Roller Material | Steel or stainless steel |

| Frame Material | Heavy-duty powder-coated steel or stainless steel |

| Roller Pitch | 150 mm to 300 mm (depending on load requirements) |

| Roller Type | Straight rollers for heavy loads |

| Drive Type | Chain-Driven, Belt-Driven, or Motorized Drive Rollers (MDR) |

| Motor Power | 1.5 kW to 5.5 kW (depending on load and speed requirements) |

| Voltage | 230V/415V, 50/60 Hz (or as per regional standards) |

| Speed | Adjustable: 5-20 m/min (standard) |

| Control System | Variable frequency drive (VFD) for speed control |

| Overall Length | Customizable (e.g., 3 m to 20 m) |

| Height | Adjustable legs (standard range: 800 mm to 1500 mm) |

| Operating Temperature | -20°C to 60°C (-4°F to 140°F) |

| Humidity | Up to 95% (non-condensing) |

| Dust/Water Resistance | IP54 or IP65 (optional) |

| Safety Features | Emergency stop buttons, side guards, roller covers, load sensors |

| Maintenance | Self-lubricating bearings, periodic greasing, easy-to-clean design |

| Optional Features | Accumulation zones, sorting systems, IoT integration, custom coatings |

| Standards | ISO 9001, CE, OSHA, ANSI |

| Certifications | RoHS, REACH (for environmental compliance) |

| Lead Time | 6-8 weeks (standard), 10-12 weeks (custom) |

| Warranty | 12 months (standard), extendable |

| Packaging | Wooden crates or pallets for safe shipping |

Related Products

Inbelts is professional portable flexible powered roller conveyors manufacturer in China. You can get all this types of flexible powered roller conveyors for goods transferring in plant like warehouse..

Pallet Roller Conveyor

A pallet roller conveyor is a heavy-duty roller conveyor specifically designed to transport pallets—flat structures used to carry goods—across various industrial settings.

Accumulation Roller Conveyor

An accumulation roller conveyor is a specialized type of roller conveyor designed to allow items to stop and accumulate at specific points along the roller conveyor system.

Powered Roller Conveyor

A powered roller conveyor is a type of roller conveyor that uses an external power source, typically an electric motor, to drive the rollers and move items along the system.

Industries

Roller conveyors play a critical role in industries that require efficient, reliable, and often heavy-duty material handling. From warehouses and manufacturing plants to airports and retail backrooms, their versatility and adaptability make them indispensable for streamlining operations and improving productivity.

- Post

- Home Appliances

- Food

- Tobacco

- Light Industries

- E-Commerce

- Retail Stores

- Manufacturing & Packaging