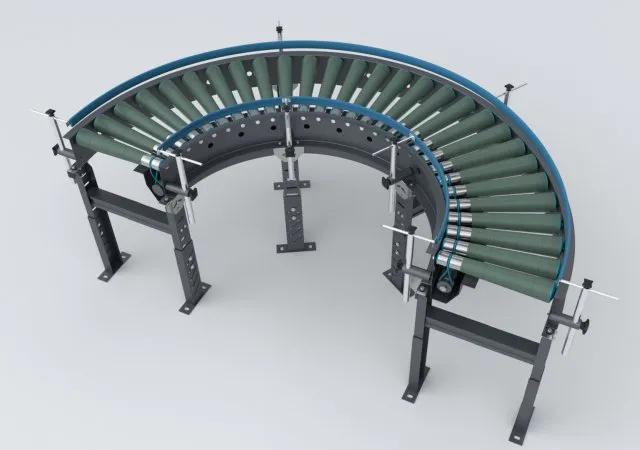

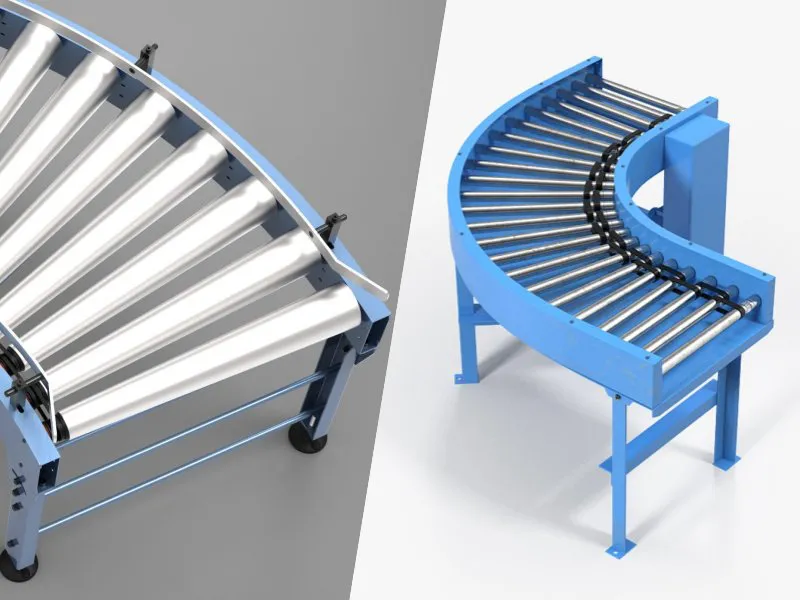

Curved roller conveyors are a practical solution for facilities requiring flexibility in layout and efficient material flow. It comes in a curved layout – usually 30°, 45°, 90° or 180°. Inbelts is a curved roller conveyor manufacturer in China. If you have a specific aspect of curved roller conveyors you'd like to explore further—such as design specifics, cost, or installation—let me know!

Design and Features of Curved Roller Conveyor

Below is a detailed overview of its design an features.

Tapered Rollers

Rollers are often tapered (wider at the outer edge, narrower at the inner edge) to ensure smooth travel around the curve. This design accounts for the difference in speed between the inner and outer paths, preventing items from slipping or jamming.

Curved Frame

The frame is constructed from durable materials like steel or aluminum, shaped into a curve to support the rollers and maintain structural integrity under load.

Drive Mechanism

- Gravity-Fed: Uses a slight incline and gravity to move items, suitable for lighter loads or shorter distances.

- Powered: Employs motors to drive the rollers, providing consistent movement for heavier loads or precise control.

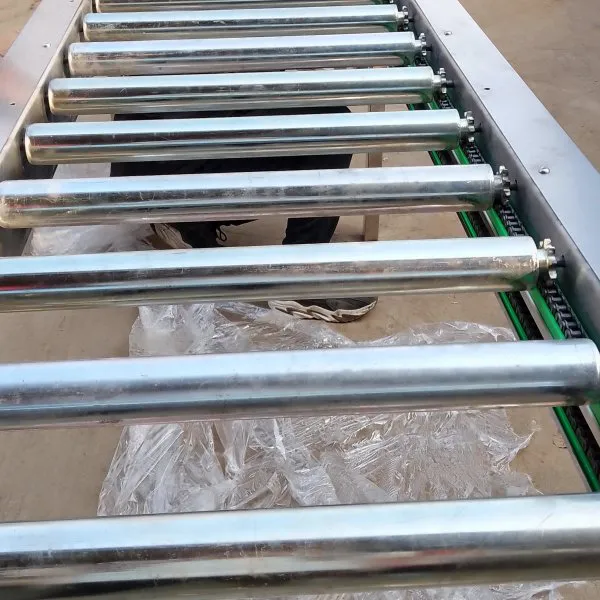

Roller Spacing

Rollers are spaced based on the size and stability of the items being transported, ensuring they stay aligned during the turn.

Side Guides or Rails

These are often included to keep goods centered and prevent them from falling off, especially critical on sharper curves or with unstable loads.

Modularity

Curved roller conveyors are often modular, allowing them to be combined with straight sections or additional curves to create a tailored conveyor system.

Load Capacity

Depending on the roller material (e.g., steel for heavy loads, plastic for lighter items) and frame strength, they can handle a range of weights, from small packages to heavy pallets.

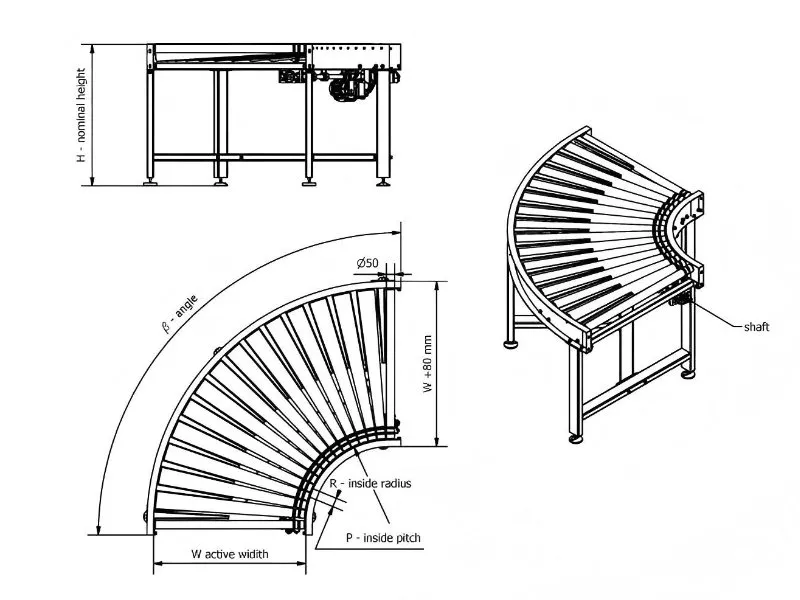

Drawings and Layout

This picture is simple layout of curved roller conveyor layout (typically at angles like 30°, 45°, 90°, or 180°).

Product Details

Advantages of Curved Roller Conveyor

- Efficient Space Utilization : Enables conveyor systems to fit into compact or irregular layouts by navigating around corners, columns, or equipment.

- Continuous Flow : Allows goods to change direction without stopping or manual intervention, maintaining workflow efficiency.

- Customizable : Available in various curve angles and sizes to suit specific operational needs.

- Versatile Integration : Easily connects with straight roller conveyors or other systems, forming a cohesive material handling network.

- Reduced Labor : Automates directional changes, minimizing the need for workers to redirect items manually.

Applications of Curved Roller Conveyor

- Warehousing and Distribution: Redirects packages or pallets around corners to sorting stations, loading docks, or storage areas, optimizing space and flow.

- Manufacturing: Connects production stages that aren't aligned in a straight line, such as moving parts from one machine to another around obstacles.

- Airport Baggage Handling: Facilitates smooth directional changes in baggage systems, transporting luggage through terminals to sorting areas or aircraft loading zones.

- E-commerce Fulfillment Centers: Manages high package volumes by directing orders to packing or shipping zones in compact, multi-directional layouts.

- Food and Beverage Processing: Moves crates, trays, or containers around bends in hygienic designs (e.g., stainless steel) that meet food safety standards.

- Retail Backrooms: Transports inventory around corners to restocking areas, streamlining operations in stores with limited space.

Curved Roller Conveyor Data Sheet

| Category | Specification |

| Type | Gravity or Unpowered or Powered (Chain-Driven, Belt-Driven, or MDR) |

| Application | Material handling in warehouses, distribution centers, manufacturing, assembly lines |

| Load Capacity | Up to 500 kg (1100 lbs) per linear meter |

| Conveyor Width | 300 mm to 1200 mm (customizable) |

| Roller Diameter | 50 mm, 60 mm, or 89 mm (standard) |

| Roller Material | Steel, stainless steel, or PVC-coated |

| Frame Material | Powder-coated steel or stainless steel |

| Curve Angle | 30°, 45°, 60°, 90°, or custom angles |

| Radius of Curve | 600 mm, 900 mm, 1200 mm (standard) |

| Roller Pitch | 75 mm to 150 mm (depending on load requirements) |

| Roller Type | Tapered rollers for smooth curve transition |

| Speed | Adjustable (for powered systems): 10-30 m/min |

| Drive Type | Gravity (no power) or Powered (Chain-driven, Belt-driven, or MDR) |

| Motor Power | 0.5 kW to 2.2 kW (for powered systems) |

| Voltage | 230V/415V, 50/60 Hz (or as per regional standards) |

| Control System | Variable frequency drive (VFD) for speed control |

| Overall Length | Customizable (e.g., 2 m to 10 m) |

| Height | Adjustable legs (standard range: 700 mm to 1200 mm) |

| Incline/Decline Angle | 5° to 10° (for gravity systems) |

| Operating Temperature | -20°C to 60°C (-4°F to 140°F) |

| Humidity | Up to 95% (non-condensing) |

| Dust/Water Resistance | IP54 or IP65 (optional) |

| Safety Features | Emergency stop buttons, side guards, roller covers, load sensors |

| Maintenance | Self-lubricating bearings, periodic greasing, easy-to-clean design |

| Optional Features | Accumulation zones, sorting systems, IoT integration, custom coatings |

| Standards | ISO 9001, CE, OSHA, ANSI |

| Certifications | RoHS, REACH (for environmental compliance) |

| Lead Time | 4-6 weeks (standard), 8-10 weeks (custom) |

| Warranty | 12 months (standard), extendable |

| Packaging | Wooden crates or pallets for safe shipping |

Related Products

Pallet Roller Conveyor

Accumulation Roller Conveyor

Powered Roller Conveyor

Industries

- Post

- Home Appliances

- Food

- Tobacco

- Light Industries

- E-Commerce

- Retail Stores

- Manufacturing & Packaging