Gravity roller conveyors are an excellent choice for simple, short-distance material handling tasks where cost and simplicity are priorities. The gravity roller conveyor frame is set at a slight downward angle (typically 1to 10) to facilitate movement. The incline can be adjustable in some designs to control speed. Inbelts is a gravity roller conveyor manufacturer in China. If you'd like more details on specific designs, load capacities, or comparisons with powered systems, just let me know!

About Gravity Roller Conveyor

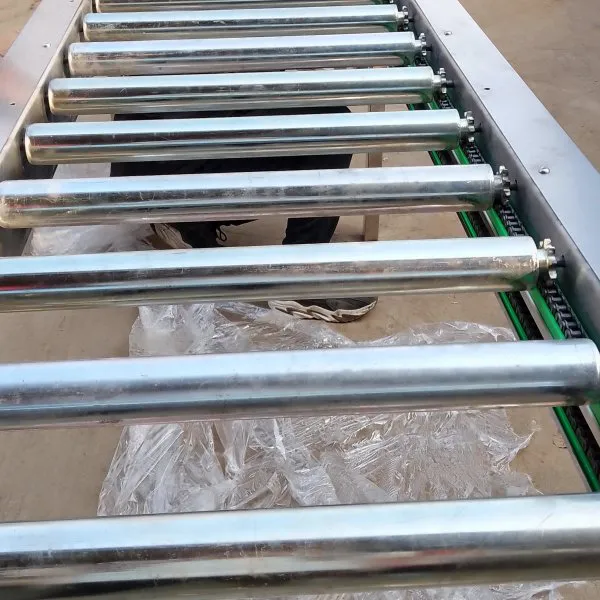

1. Conveyor Rollers

- Made from materials like steel, aluminum, or plastic, depending on the load requirements. Steel rollers are durable for heavy items, while plastic rollers suit lighter or delicate goods.

- Rollers are free-spinning, allowing items to move under gravity's pull.

2. Inclined Frame

- The frame is set at a slight downward angle (typically 1-5 degrees or 1 - 10 degrees) to facilitate movement. The incline can be adjustable in some designs to control speed.

- Constructed from sturdy materials like steel or aluminum to support the load.

3. Roller Spacing

Spacing between rollers is customized based on the size and weight of items to ensure smooth travel without tipping or jamming.

4. Side Guides or Rails

Optional guides keep items aligned and prevent them from sliding off the sides, especially on wider conveyors or with unstable loads.

5. Braking or Speed Control (Optional)

Some gravity roller conveyors include brakes, dampers, or speed controllers to slow down items, preventing damage or runaway loads on steeper inclines.

6. Modularity

Many designs are modular, allowing sections to be added, removed, or combined with other conveyor types (e.g., curved sections).

7. Portable Options

Lightweight models with wheels or collapsible frames are available for temporary or flexible use.

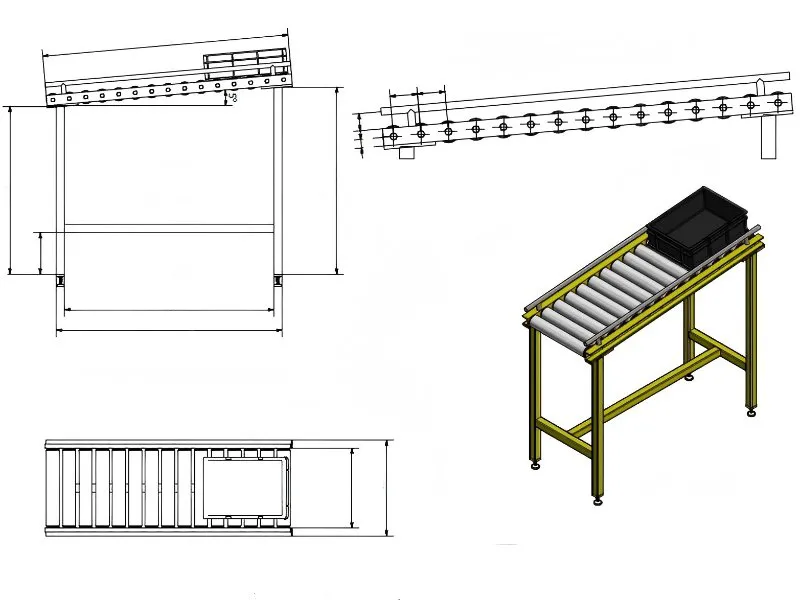

Drawings and Layout

This picture is simple layout of gravity roller conveyor layout (we can provide curved gravity roller conveyor and straight gravity roller conveyor).

Product Details

Advantages of Gravity Roller Conveyor

- Cost-Effective: No electricity or motors are required, reducing initial purchase costs and eliminating operational energy expenses.

- Low Maintenance: With few moving parts, gravity roller conveyors are simple to maintain and have a long lifespan.

- Easy Installation: Lightweight and straightforward design allows for quick setup without specialized tools or expertise.

- Energy Efficient: Relies entirely on gravity, making it an eco-friendly option with zero power consumption.

- Quiet Operation: Lacks motorized components, resulting in minimal noise compared to powered conveyors.

- Flexible Use: Adjustable incline and portable options make it adaptable to various tasks or temporary setups.

Applications of Gravity Roller Conveyor

- Warehousing and Distribution: Moves boxes or packages from one area to another, such as unloading trucks to sorting zones or transferring goods to storage racks.

- Assembly Lines: Transports components between workstations in manufacturing plants, especially for lightweight parts in short-distance setups.

- Shipping and Receiving: Facilitates loading and unloading of goods in docks, often used as a temporary or portable solution for moving packages into or out of trucks.

- Retail and Order Picking: Assists in backroom operations by moving inventory from storage to packing areas, particularly in small-scale or temporary setups.

- Packaging Lines: Transfers finished products (e.g., boxed goods) to sealing or shipping stations in low-volume production environments.

- Temporary Workstations: Portable gravity roller conveyors are used in construction sites, events, or pop-up facilities to move materials quickly and cheaply.

Gravity Roller Conveyor Data Sheet

| Category | Specification |

| Type | Gravity (Non-Powered) |

| Application | Material handling in warehouses, distribution centers, manufacturing, assembly lines |

| Load Capacity | Up to 300 kg (660 lbs) per linear meter |

| Conveyor Width | 300 mm to 1200 mm (customizable) |

| Roller Diameter | 50 mm, 60 mm, or 89 mm (standard) |

| Roller Material | Steel, stainless steel, or PVC-coated |

| Frame Material | Powder-coated steel or stainless steel |

| Roller Pitch | 75 mm to 150 mm (depending on load requirements) |

| Roller Type | Straight or tapered rollers (for curved sections) |

| Incline/Decline Angle | 5° to 10° (adjustable) |

| Overall Length | Customizable (e.g., 2 m to 10 m) |

| Height | Adjustable legs (standard range: 700 mm to 1200 mm) |

| Operating Temperature | -20°C to 60°C (-4°F to 140°F) |

| Humidity | Up to 95% (non-condensing) |

| Dust/Water Resistance | IP54 (optional) |

| Safety Features | Side guards, roller covers, and end stops |

| Maintenance | Self-lubricating bearings, periodic greasing, easy-to-clean design |

| Optional Features | Curved sections, brakes, or flow rails for controlled movement |

| Standards | ISO 9001, CE, OSHA, ANSI |

| Certifications | RoHS, REACH (for environmental compliance) |

| Lead Time | 2-4 weeks (standard), 6-8 weeks (custom) |

| Warranty | 12 months (standard), extendable |

| Packaging | Wooden crates or pallets for safe shipping |

Related Products

Pallet Roller Conveyor

Accumulation Roller Conveyor

Powered Roller Conveyor

Industries

- Post

- Home Appliances

- Food

- Tobacco

- Light Industries

- E-Commerce

- Retail Stores

- Manufacturing & Packaging