The Ultimate Guide to Roller Conveyors for Unloading Trucks

In the fast-paced world of logistics and material handling, efficiency and speed are paramount. One of the key pieces of equipment that can significantly enhance productivity is the roller conveyor. Particularly useful for unloading trucks, roller conveyors streamline the transfer of goods, reducing manual labor and increasing throughput. This guide will delve into the various aspects of roller conveyors, providing comprehensive insights into their types, benefits, installation, maintenance, and more.

What is a Roller Conveyor?

A roller conveyor is a type of conveyor system that uses a series of rollers to move materials. These conveyors are typically used in warehouses, distribution centers, and manufacturing facilities to transport goods quickly and efficiently. The rollers can be powered or unpowered, depending on the specific needs of the operation. We provide portable conveyor for warehouse management.

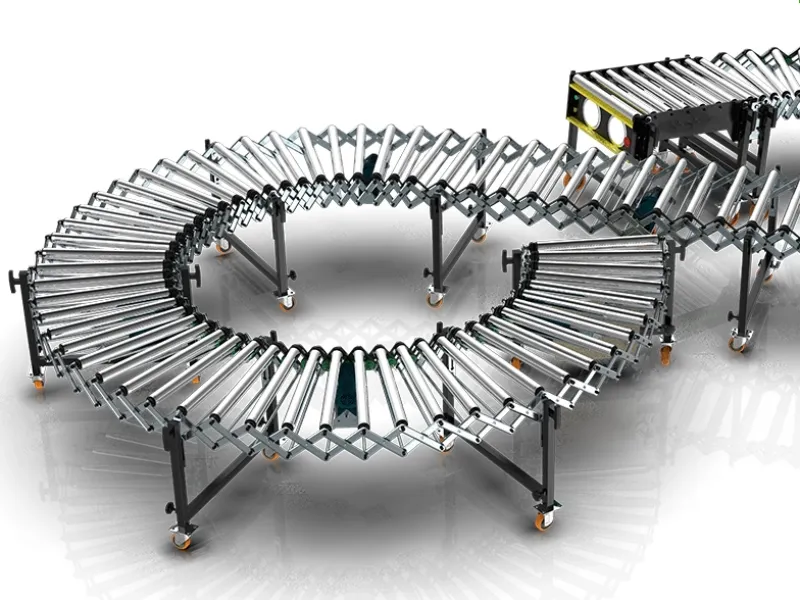

Flexible Roller Conveyor Truck Unloading

Definition and Functionality

Roller conveyors consist of cylindrical rollers set within a frame. Materials move over these rollers either by gravity or through mechanical means. The primary function of a roller conveyor is to facilitate the easy and efficient movement of goods from one point to another, minimizing manual handling.

History of Roller Conveyors

The concept of conveyors dates back to ancient times, but the modern roller conveyor has evolved significantly. Initially developed to reduce the labor-intensive process of moving goods, roller conveyors have undergone numerous technological advancements. Today, they are integral to automated material handling systems.

Evolution of Conveyor Technology

From rudimentary wooden logs used in ancient times to sophisticated, automated systems in contemporary warehouses, conveyor technology has come a long way. Innovations in materials, motor technology, and control systems have continually enhanced the efficiency and capabilities of roller conveyors.

Types of Roller Conveyors

There are several types of roller conveyors, each designed for specific applications and operational needs.

- Gravity Roller Conveyors: These conveyors rely on gravity to move materials. They are ideal for applications where the conveyor must be horizontal or slightly inclined.

- Powered Roller Conveyors: Powered by motors, these conveyors provide a consistent flow of materials. They are used when items need to be moved over longer distances or through multiple stages of a process.

- Flexible Roller Conveyors: Our flexible roller conveyors can be bent and curved as needed, making them perfect for temporary or dynamic setups.

- Expandable Roller Conveyors: These conveyors can be expanded or contracted to fit different lengths, offering great versatility for various loading and unloading scenarios.

Truck Unloading Conveyor System with Flexible Roller Conveyor

Benefits of Using Roller Conveyors for Unloading Trucks

Using roller conveyors for unloading trucks comes with several advantages.

- Increased Efficiency: Roller conveyors significantly speed up the unloading process, allowing more goods to be processed in less time.

- Reduced Labor Costs: By automating the movement of goods, roller conveyors reduce the need for manual labor, cutting down on labor costs.

- Improved Safety: Conveyors minimize the physical strain on workers, reducing the risk of injuries associated with heavy lifting and repetitive motions.

Key Components of Roller Conveyors

Understanding the components of roller conveyors is crucial for selecting and maintaining them.

1. Rollers

The primary components that support and move the materials. Rollers come in various sizes and materials to suit different applications.

2. Fames

The structure that holds the rollers in place. Frames need to be sturdy and durable to support the weight of the materials.

3. Bearings

Bearings allow the rollers to spin smoothly and reduce friction.

4. Drive Mechanisms

In powered conveyors, drive mechanisms are what move the rollers. These can include motors, belts, and chains.

How to Choose the Right Roller Conveyor

Choosing the right roller conveyor involves several considerations.

1. Load Capacity

The conveyor must be able to support the weight of the materials being transported.

2. Conveyor Length

The length of the conveyor should be appropriate for the distance over which materials need to be moved.

3. Roller Diameter

Larger rollers can support heavier loads and reduce the risk of jams.

4. Material Type

Rollers and frames should be made from materials suitable for the operational environment, such as stainless steel for food processing.

Installation of Roller Conveyors

Proper installation is critical to ensure the safe and efficient operation of roller conveyors.

- Site Preparation: The installation site should be clean, level, and free of obstructions.

- Assembly Instructions: Follow the manufacturer’s assembly instructions carefully to ensure all components are installed correctly.

- Safety Precautions: Ensure all safety measures are in place, including emergency stops and guards to protect operators from moving parts.

Maintenance of Roller Conveyors

Regular maintenance ensures the longevity and efficiency of roller conveyors.

- Regular Inspections: Conduct regular inspections to identify and address any wear or damage.

- Lubrication: Keep all moving parts properly lubricated to prevent friction and wear.

- Troubleshooting Common Issues: Address common issues such as misaligned rollers or malfunctioning motors promptly to avoid operational downtime.

Applications of Roller Conveyors

Roller conveyors are versatile and can be used in various industries.

- Warehousing: Used for sorting and moving goods within warehouses.

- Manufacturing: Facilitate the movement of parts and products through different stages of production.

- Distribution Centers: Enable the quick and efficient handling of packages and goods.

- Retail: Assist in the movement of products from storage areas to the sales floor.

Roller Conveyors vs. Belt Conveyors

While both roller and belt conveyors are used for material handling, they have distinct differences.

- Comparison of Features: Roller conveyors are typically better for handling heavy loads, while belt conveyors are suited for smaller, more delicate items.

- Pros and Cons: Roller conveyors are generally more durable and require less maintenance, but belt conveyors offer more versatility in terms of the types of materials they can move.

Technological Advancements in Roller Conveyors

Recent technological advancements have further enhanced the capabilities of roller conveyors.

- Automation: Automated systems can control the movement of materials with minimal human intervention.

- Smart Sensors: Sensors can monitor the position and movement of materials, ensuring smooth and efficient operations.

- Integration with Warehouse Management Systems: Conveyors can be integrated with warehouse management systems for improved inventory tracking and order fulfillment.

Cost Analysis

Understanding the costs associated with roller conveyors can help in making informed decisions.

- Initial Investment: Consider the upfront cost of purchasing and installing the conveyor system.

- Operating Costs: Factor in the costs of maintenance, energy consumption, and potential downtime.

- Return on Investment: Evaluate the long-term benefits and savings to determine the return on investment.

How to Optimize Roller Conveyors for Efficiency

Implementing best practices can maximize the efficiency of roller conveyors.

- Best Practices: Adopt strategies such as regular maintenance and employee training to ensure optimal performance.

- Employee Training: Proper training ensures that employees can operate and maintain the conveyors safely and effectively.

Safety Measures for Using Roller Conveyors

Safety is paramount when operating roller conveyors.

- Operator Training: Comprehensive training programs can prevent accidents and injuries.

- Equipment Safety Features: Ensure that conveyors are equipped with necessary safety features like emergency stops and guards.

- Emergency Procedures: Establish clear emergency procedures to handle any incidents promptly.

FAQs about Roller Conveyors for Unloading Trucks

1. How do roller conveyors work?

Roller conveyors use a series of rollers to move materials by gravity or mechanical means.

2. What are the types of roller conveyors?

Common types include gravity roller conveyors, powered roller conveyors, flexible roller conveyors, and expandable roller conveyors.

3. What are the benefits of using roller conveyors for unloading trucks?

They increase efficiency, reduce labor costs, and improve safety.

4. How do you maintain roller conveyors?

Regular inspections, proper lubrication, and prompt troubleshooting of issues are essential.

5. What factors should be considered when choosing a roller conveyor?

Consider load capacity, conveyor length, roller diameter, and material type.

6. Can roller conveyors be customized?

Yes, they can be tailored to meet specific operational and industry requirements.

Roller conveyors are indispensable in modern material handling, particularly for unloading trucks. Their versatility, efficiency, and ease of use make them a valuable asset in various industries. By understanding their components, benefits, and maintenance needs, businesses can optimize their operations and improve productivity. As technology advances, roller conveyors will continue to evolve, offering even greater capabilities and efficiencies in the future.

Leave Me Your Requirement!