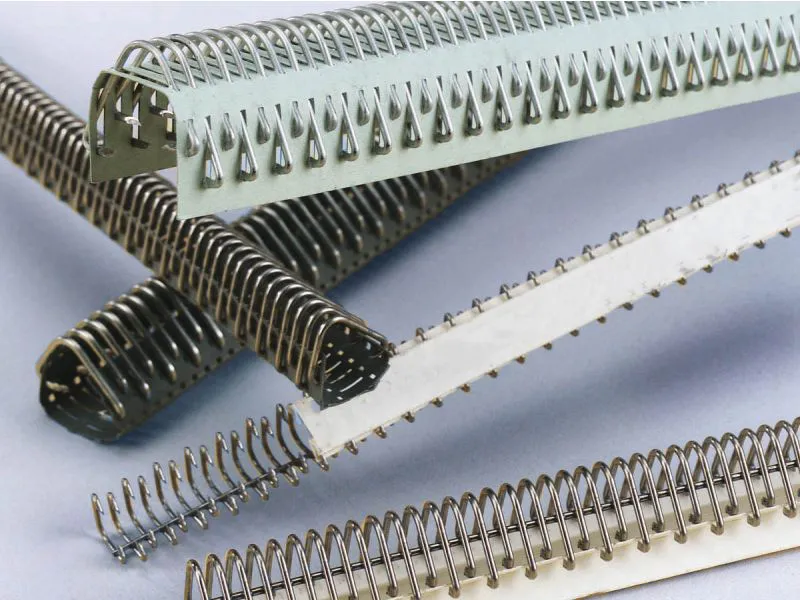

How to Select Wire Hook Belt Fastener for Light Duty Conveyor Belt?

The wire hook fastener is a type of belt joins for industrial belts. There is main five steps to select wire hook belt fastener for light duty conveyor belt. We will talk about how to choose wire hook belt fastener right.

Step1: Measure Conveyor Belt Thickness

Measure belt thickness with hook gauge, micrometer, or caliper. If the belt has an impression cover, skive the impression off prior to measuring the thickness.

Step2: Measure Pulley Diameter

Inspect the belt line for the smallest pulley that has a belt wrap of at least 90 degrees. This will be your ‘minimum pulley diameter’ measurement.

Step3: Determine Hook Choices

Referencing the Fastener Selection Chart, identify possible fastener choices based on the belt thickness and minimum pulley diameter. Note: For any given belt thickness there are a number of hooks that can be selected.

- The belt thickness: 0.6 - 10.0mm.

- The minimum pulley diameter: 24mm - 175mm.

Step4: Select Wire Diameter/Shape

Belt Fasteners made from a smaller diameter offer:

- Less noise as the splice contacts conveyor components.

- Less wear on conveyor components.

Belt Fasteners made from a larger diameter offer:

- Added strength for the increased wire mass.

- Added wear resistance.

Step5: Select Wire Hook Metal Material

There are about 12 kinds of materials which are used to process wire hook belt fastener. We list common items:

- Galvanized

- Steel (High Tensile or Rectangular High Tensile)

- 430 Stainless Steel

- 316 Stainless Steel

Leave Me Your Requirement!