How to Measure a Industrial Conveyor Belt?

When it's time to replace a conveyor belt, you could simply cut the old belt, remove it from the machine, lay it flat, and measure it with a tape measure to determine the pre-tensioned length. However, this method causes significant downtime, leaving the conveyor out of commission until the new belt arrives. Most likely, this isn't a viable option—you need to order the replacement belt before the old one fails and install the new belt immediately after removing the old one. Therefore, it's beneficial to know how to measure a conveyor belt while it's still on the conveyor system using the center-to-center distance formula.

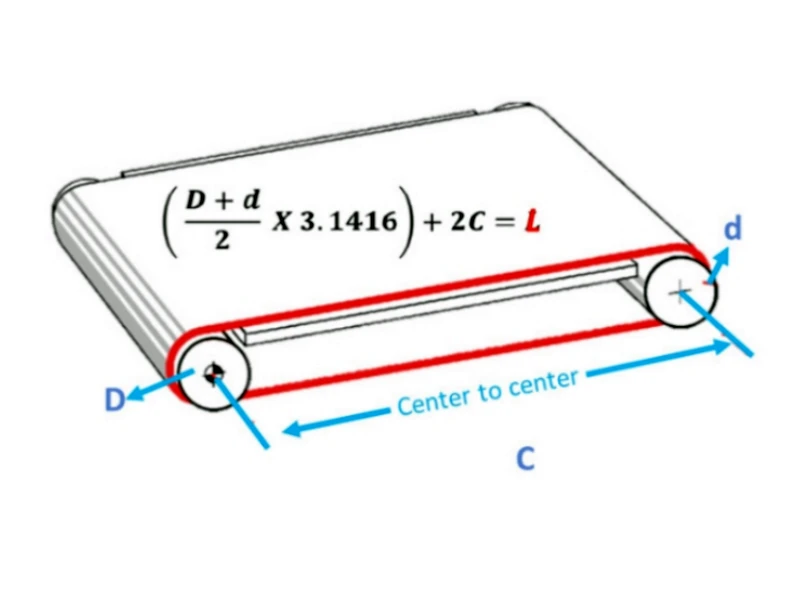

The Center-to-Center Distance Formula

This formula is one of the most reliable methods for determining the correct length of the replacement conveyor belt. It refers to the distance between the centers of your conveyor's drive and tail pulleys. Here's the formula:

Note: This formula can ONLY be used on 2 pulley systems.

L=2C+π(D+d)/2

Where:

- L = belt length (inches)

- C= center-to-center distance (inches)

- π= 3.1416

- D= diameter of the large pulley (inches)

- d= diameter of the small pulley (inches)

Understanding the Formula

- 2C: Multiplying the center-to-center distance by 2 accounts for the belt length on the top and bottom of the pulleys.

- (D+d)/2: This accounts for the belt length wrapped around the outer half of the pulleys' circumference.

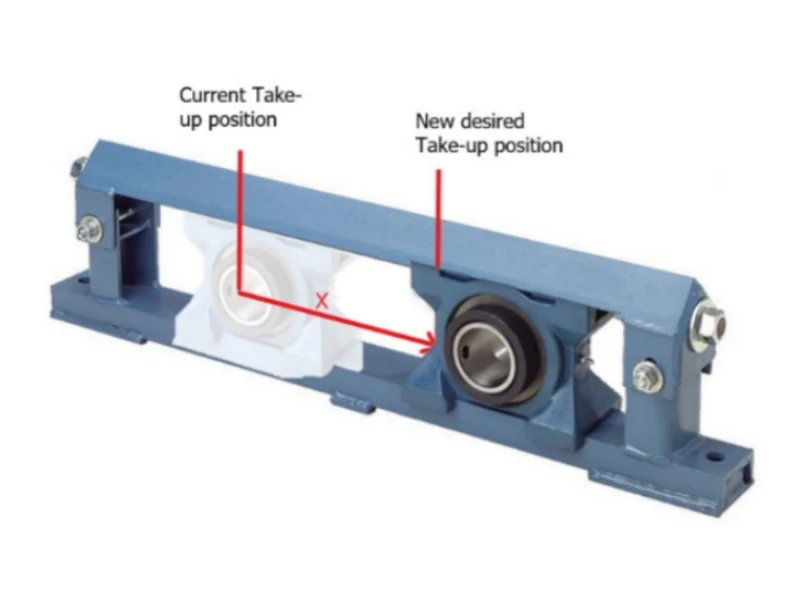

This calculation yields the belt's stretched length. Make sure to note the location of the take-ups on your system. If take-ups are maxed out, you might want to adjust them to the center location and remeasure your center-to-center distance to allow for adjustment after the belt is running.

How Does Take-Up Adjustment Affect Belt Length?

Adjusting take-up assemblies can affect belt length. Here's a simple way to calculate the belt length change after a take-up adjustment:

(2X)±L1=L2

Where:

- X= Desired take-up adjustment

- L1 = Original belt length (before take-up adjustment)

- L2= New belt length (after take-up adjustment)

Example:

- Current belt length: 275 inches

- Moving the take-up out (towards the end of the conveyor) by 5 inches

- New belt length: 275+10=285inches

Measuring Belt Length with More Than Two Pulleys

For systems with more than two pulleys, use the start and stop technique:

- Mark the top side of the belt with a starting mark labeled "0".

- Find the furthest accessible point down the belt, make a second mark, and measure the distance between the two marks.

- Jog the system until the second mark reaches the "0" mark position, then make a third mark further down the belt.

- Measure the distance between the new marks.

- Continue this process until your final measurement ends with the "0" mark.

- Add all measurements together to find the total belt length.

Note: This process usually requires two people. Ensure all hands, pens, and measurement devices are clear before jogging the system.

Precision is Key

Incorrectly measuring the center-to-center distance or pulley diameter, applying the wrong tension, or making mathematical errors will result in a flawed belt length calculation. Ordering the wrong belt dimensions can lead to:- Extended downtime

- Additional costs

- Lower production numbers

- And more

Leave Me Your Requirement!