Telescopic Conveyor for Truck Unloading: Revolutionizing Material Handling

The logistics and material handling industry is continually evolving, seeking innovative solutions to enhance efficiency and reduce labor costs. One such advancement is the telescopic conveyor system, designed specifically for truck unloading. This technology has transformed the way goods are moved from trucks to warehouses, offering significant improvements in speed, safety, and operational efficiency.

What is a Telescopic Conveyor?

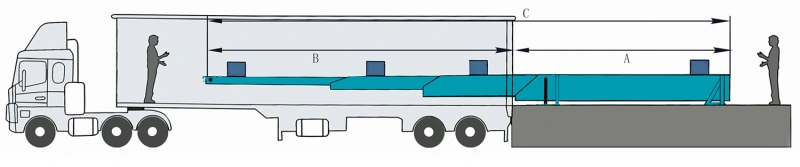

A telescopic conveyor is an extendable conveyor system that can be adjusted in length to reach the back of a truck or container. Typically, these conveyors consist of multiple sections that slide into each other, much like the segments of a telescope. This flexibility allows the conveyor to be extended or retracted to suit the loading or unloading process, making it an ideal solution for environments with varying truck sizes and dock configurations.

Key Features and Benefits

1. Enhanced Efficiency

Telescopic conveyors significantly reduce the time required for unloading trucks. By extending directly into the truck, they eliminate the need for manual handling of goods, which speeds up the unloading process. This increased efficiency can lead to faster turnaround times, allowing trucks to get back on the road sooner.

2. Labor Savings

Manual unloading is labor-intensive and often requires multiple workers. A telescopic conveyor reduces the physical strain on workers and minimizes the number of personnel needed for unloading tasks. This not only lowers labor costs but also reduces the risk of workplace injuries related to heavy lifting and repetitive motion.

3. Flexibility and Adaptability

These conveyors can be adjusted to different lengths and heights, making them suitable for various types of trucks and loading docks. Some models even feature adjustable inclination angles, further enhancing their versatility. This adaptability ensures that the conveyor can be used in a wide range of scenarios, from small delivery vans to large freight containers.

4. Improved Safety

Safety is a critical concern in material handling operations. Telescopic conveyors improve safety by reducing the need for manual lifting and carrying of goods. Additionally, many telescopic conveyors come equipped with safety features such as emergency stop buttons, anti-collision systems, and ergonomic controls, ensuring a safer working environment for operators.

5. Space Optimization

When not in use, telescopic conveyors can be retracted to save space. This compact storage capability is particularly beneficial for facilities with limited space, allowing them to maximize their available area for other operations or equipment.

Applications in Various Industries

Telescopic conveyors are used across a range of industries due to their versatility and efficiency. Some common applications include:

- Retail and E-commerce: Rapid unloading of goods from delivery trucks to fulfillment centers.

- Food and Beverage: Handling of packaged food products and beverages, ensuring quick turnaround times and maintaining the cold chain.

- Automotive: Efficient movement of parts and components in automotive manufacturing plants.

- Parcel and Courier Services: Fast unloading of parcels and packages in distribution centers, supporting high-volume logistics operations.

The telescopic conveyor for truck unloading is a game-changer in the material handling industry. Its ability to streamline the unloading process, reduce labor costs, enhance safety, and adapt to various operational needs makes it an invaluable asset for businesses. As logistics and supply chain demands continue to grow, the adoption of telescopic conveyors is likely to become increasingly widespread, driving further advancements in efficiency and productivity.

Investing in a telescopic conveyor system can provide substantial returns, not only in terms of cost savings but also in improving overall operational efficiency. For businesses looking to stay competitive in a fast-paced market, embracing this technology is a strategic move towards a more efficient and effective material handling process.

Leave Me Your Requirement!