Roller Conveyor Side Rails for Operation Protection

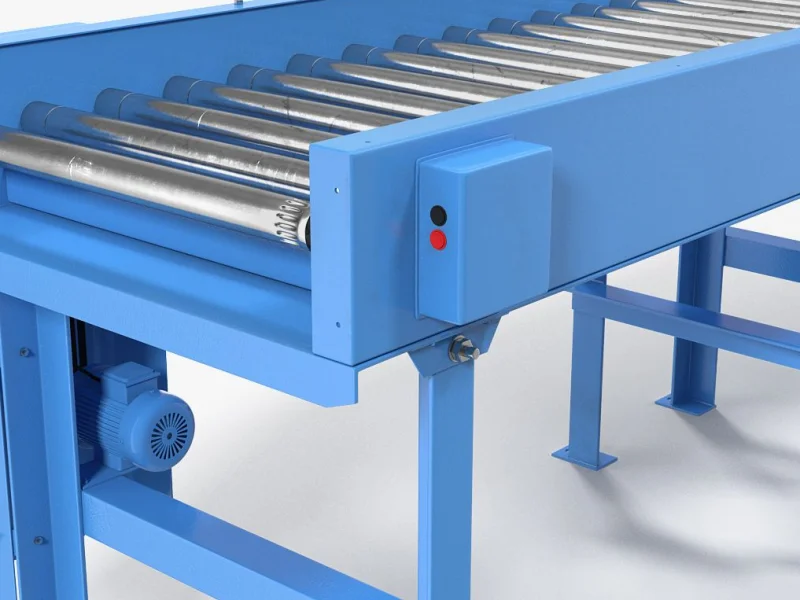

Roller conveyor side rails are structural components attached to the sides of a roller conveyor to guide loads, prevent items from shifting or falling off, and enhance safety. They are particularly important for:

- Alignment: Keeping items (e.g., boxes, pallets, totes) centered on the conveyor, especially around curves or during high-speed operation.

- Safety: Protecting operators and preventing loads from derailing, especially for unstable or heavy items.

- Stability: Supporting items on inclines, declines, or during accumulation.

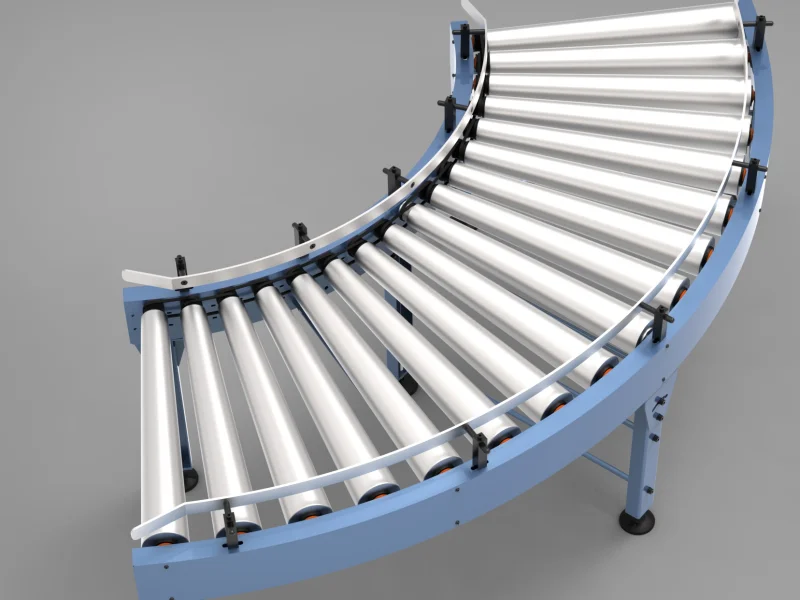

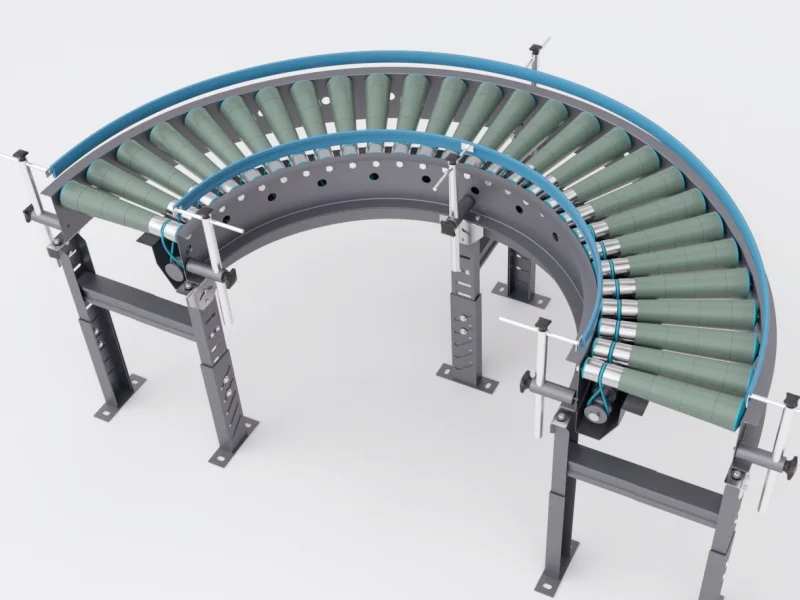

Side rails are used in all types of roller conveyors, including gravity, powered, chain-driven, accumulation, pallet, and curved systems.

Purpose of Roller Conveyor Side Rails

Prevent Load Derailment: Stop items from sliding off due to misalignment, curves, or external forces (e.g., forklift bumps).

- Guide Loads: Ensure consistent positioning for downstream processes (e.g., sorting, packing).

- Protect Operators: Reduce risks of items falling onto workers or walkways.

- Support Accumulation: Keep queued items aligned in accumulation conveyors.

- Enhance Stability: Critical for unstable loads (e.g., stacked boxes, loose items) or high-speed conveyors.

Types of Roller Conveyor Side Rails

1. Fixed Side Rails

- Description: Permanently attached to the conveyor frame via bolts or welds.

- Use Case: Stable, repetitive loads (e.g., pallets, uniform boxes).

- Height: 1"–6" (common: 2" for boxes, 4"–6" for pallets).

- Material: Steel, aluminum, or stainless steel.

- Pros: Durable, low maintenance.

- Cons: Less flexible for varying load sizes.

2. Adjustable Side Rails

- Description: Mounted on brackets or slots, allowing width or height adjustments.

- Use Case: Variable load sizes (e.g., mixed boxes, totes).

- Height: 1"–12" (adjustable via clamps or screws).

- Material: Steel or aluminum, sometimes with plastic inserts.

- Pros: Versatile, easy to reconfigure.

- Cons: Higher cost, may loosen over time.

3. Roller Side Guides

- Description: Small rollers or wheels mounted vertically along the rail to reduce friction.

- Use Case: Fragile loads (e.g., electronics, glass) or high-speed conveyors.

- Height: 2"–6".

- Material: Steel frame with plastic or urethane rollers.

- Pros: Minimizes damage to delicate items.

- Cons: More expensive, requires roller maintenance.

4. Channel Side Rails

- Description: U-shaped or C-shaped channels that cradle loads.

- Use Case: Small or unstable items (e.g., loose parts, narrow totes).

- Height/Width: 1"–4" high, 1"–2" wide.

- Material: Steel, aluminum, or plastic.

- Pros: Secure containment.

- Cons: Limited to specific load sizes.

5. Flared or Angled Side Rails

- Description: Wider at the top (e.g., funnel-shaped) to guide misaligned loads back to center.

- Use Case: Curved conveyors, inclines, or high-speed systems.

- Height: 2"–8".

- Material: Steel or aluminum.

- Pros: Corrects misalignment.

- Cons: Bulkier, higher cost.

6. Custom Side Rails

- Description: Tailored for unique loads or environments (e.g., food-grade, high-impact).

- Use Case: Specialized applications (e.g., chemical plants, cold storage).

- Material: Stainless steel, reinforced plastic, or coated steel.

- Pros: Perfect fit for specific needs.

- Cons: Expensive, longer lead times.

Design Considerations for Side Rails

1. Height

- Match to load height and stability:

- Low (1"–2"): Small, stable boxes or totes.

- Medium (2"–4"): Standard boxes, light pallets.

- High (4"–8"): Heavy pallets, unstable stacks.

- Ensure clearance for loading/unloading (e.g., forklift access for pallets).

2. Width/Clearance

- Allow 1"–2" clearance per side for smooth flow (e.g., 12" wide box needs 14"–16" between rails).

- Adjustable rails accommodate varying widths.

3. Material

- Steel: Durable, cost-effective; powder-coated or galvanized for rust resistance.

- Aluminum: Lightweight, corrosion-resistant; ideal for portability.

- Stainless Steel: Food-grade, washdown, or corrosive environments.

- Plastic/Urethane: Low friction, protects delicate loads.

4. Mounting

- Bolted: Secure, for fixed rails.

- Slotted/Adjustable: Flexible, for variable loads.

- Welded: Permanent, for heavy-duty systems.

5. Load Dynamics

- Curves: Use flared or roller guides to handle speed differentials.

- Inclines/Declines: Higher rails (e.g., 4"–6") to prevent tipping.

- Accumulation: Smooth or roller guides to avoid damage during queuing.

6. Safety

- Smooth edges to avoid operator injury or load damage.

- High-visibility coatings (e.g., yellow) for safety zones.

- Ensure rails don't obstruct emergency access.

How to Choose Side Rails for a Roller Conveyor

1. Define Load Requirements

- Size: E.g., 12" x 10" boxes need ~14"–16" rail spacing.

- Weight: Heavy pallets (1,000 lbs+) need taller, stronger rails (4"–6").

- Stability: Unstable loads (e.g., stacked boxes) require higher or flared rails.

2. Assess Conveyor Type

- Gravity: Fixed or adjustable rails for simple guidance.

- Powered/Chain-Driven: Adjustable or roller guides for high-speed or accumulation.

- Curved: Flared or roller guides to manage load shifts.

- Pallet: High, sturdy rails (4"–8") for heavy loads.

3. Consider Environment

- Dry/Indoor: Steel or aluminum rails.

- Washdown/Food-Grade: Stainless steel or plastic.

- Corrosive/Outdoor: Galvanized steel or aluminum.

4. Evaluate Adjustability

- Fixed rails for consistent loads; adjustable for mixed sizes.

- Roller guides for delicate or high-speed applications.

5. Check Compatibility

- Ensure rail mounting fits conveyor frame (e.g., bolt holes, slot spacing).

- Verify height doesn't interfere with other components (e.g., sensors, motors).

6. Budget and Maintenance

- Steel rails: Cheapest ($5–$20/ft).

- Stainless steel: More expensive ($10–$50/ft).

- Roller guides: Highest cost ($20–$100/ft).

- Maintenance: Inspect for dents, rust, or loose bolts quarterly.

Pricing for Side Rails

Fixed Steel Rails:

- 1"–2" high: $5–$10 per foot.

- 4"–6" high: $10–$20 per foot.

- Example: 10' of 4" steel rails ≈ $100–$200.

Fixed Aluminum Rails:

- 2"–4" high: $8–$15 per foot.

- Example: 10' of 2" aluminum ≈ $80–$150.

Stainless Steel Rails:

- 2"–4" high: $15–$50 per foot.

- Example: 10' of 4" stainless ≈ $150–$500.

Adjustable Rails:

- Steel: $10–$25 per foot.

- Aluminum: $15–$30 per foot.

Roller Side Guides:

- Plastic/urethane rollers: $20–$100 per foot.

- Example: 10' of roller guides ≈ $200–$1,000.

Flared/Angled Rails:

- Steel: $15–$30 per foot.

- Mounting Brackets/Clamps: $5–$20 each (4–8 needed per 10').

Installation and Maintenance Tips

Installation:

- Bolt or clamp rails to conveyor frame, ensuring alignment with roller surface.

- Space rails 1"–2" wider than load for clearance.

- Use adjustable brackets for flexibility.

Maintenance:

- Inspect quarterly for dents, rust, or loose bolts.

- Clean stainless steel rails in washdown environments to prevent contamination.

- Replace bent or damaged rails to avoid load jams.

- Spare Parts: Stock 10'–20' of rails per conveyor to cover wear or impact damage.

Example Selection

- Scenario: A 15' chain-driven roller conveyor for 1,000-lb pallets (48" x 40").

- Conveyor Specs: 54" wide, 2.5" steel rollers, #50 chain.

- Side Rail Needs:

- Type: Fixed steel, 4" high for pallet stability.

- Spacing: 50" between rails (48" pallet + 2" clearance).

- Length: 15' per side (30' total).

- Material: Galvanized steel (indoor warehouse).

- Cost: 30' × $15/ft = $450.

- Source: Inbelts.

- Spare Parts: Stock 10' extra rail ($150) for replacements.

Side rails for roller conveyors ensure load alignment and safety, with types ranging from fixed steel ($5–$20/ft) to adjustable roller guides ($20–$100/ft). Selection depends on load size, conveyor type, and environment. If you need a specific rail type, pricing for a particular conveyor, or design details, share your conveyor specs (e.g., width, load, type), and I'll refine the response!

Leave Me Your Requirement!