10 Tips to Drcrease Downtime and Increase Conveyor Belt Efficiency

Conveyor systems are crucial in manufacturing plants and distribution centers, enhancing worker safety and productivity. When designed and operated efficiently, conveyors streamline the movement of products, components, and packaging. However, a conveyor belt malfunction can cause significant disruptions, leading to workflow bottlenecks, material pile-ups, inventory damage, and potential safety hazards.

Ensuring Optimal Conveyor Belt Efficiency

Maintaining conveyor belt efficiency is key to keeping production running smoothly and creating a safe work environment. Preventive measures and regular maintenance are essential to avoid costly and stressful system stalls.

Pre-Production Belt Selection Tips

Before your plant begins operations, consider these factors to enhance belt conveyor efficiency:

1. Understand Load Characteristics

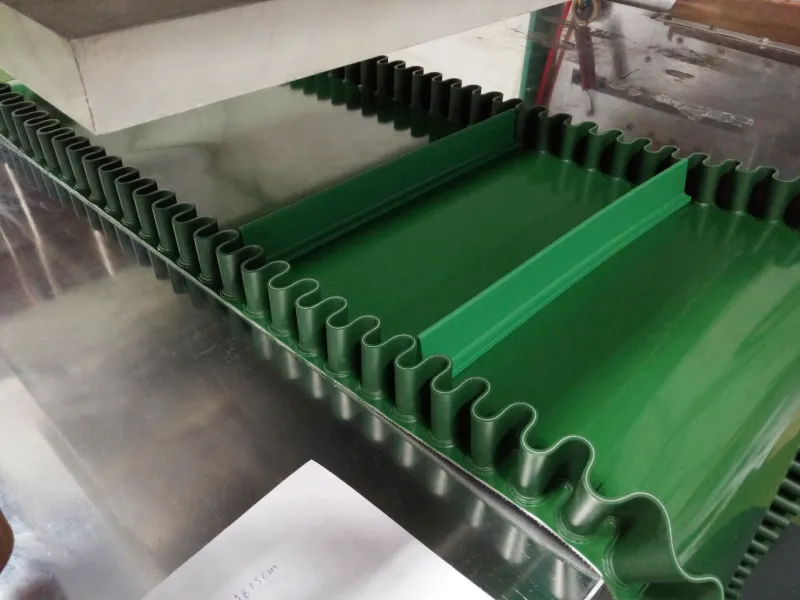

Assess the size, weight, dimensions, and other attributes of the loads your conveyor will transport. This information helps determine the appropriate belt material, motor, drive, and hardware. Consider temperature and material properties as well. Learn about the differences between conventional belting and plastic modular belting, and consult with a belt expert to explore all options.

2. Optimize Conveyor Direction

Set your conveyors to pull rather than push, as pulling is more efficient and can retain 50-70% more load capacity.

3. Consider Flow Rate

Determine the speed and precision required for material feeding or removal. For fast-moving applications, such as in distribution centers and airports, you’ll need suitable fasteners, endless splicing equipment, segmented transfer plates, and maintenance tools.

4. Know Industry Requirements

For food, beverage, or pharmaceutical products, consider material density, hygiene, and sanitation factors. Often, an FDA-approved conveyor belt is necessary.

Production Conveyor Belt Maintenance Tips

Regular inspection and preventive maintenance can save money and prevent major failures that could damage products, endanger employees, or cause downtime.

1. Routine Inspections

Follow the manufacturer's recommendations for daily, weekly, monthly, and quarterly inspections of bearings, pulleys, and other components. Ensure your maintenance team records each inspection and preventive action taken.

2. Regular Cleaning

Maintain a cleaning regimen to reduce energy usage, friction, and slippage, which can extend the life of motors, rollers, and other moving parts. Depending on your industry, a clean-in-place system may be beneficial.

3. Proactive Parts Replacement

Implement predictive maintenance to avoid catastrophic breakdowns and maintain productivity. Keep critical parts on hand or partner with a reliable conveyor belt supplier for quick replacements.

Safety, Training, and Logistics Tips

To maximize conveyor belt productivity, ensure systems are correctly placed and used safely.

1. Inspect and Calibrate

Regularly check safety mechanisms, such as pull stops, machine guards, railings, and warning labels. Ensure conveyors are calibrated and adjusted to meet standards and remain user-friendly.

2. Design Ergonomic Workstations

If your conveyor is part of a workstation, design it to minimize bending, reaching, and twisting. Adjust the conveyor height for the tallest operator and provide platforms for shorter workers. Ensure items are easily accessible.

3. Promote a Safety Culture

Encourage workers to report safety concerns and suggest improvements. Enforce a zero-tolerance policy for conveyor misuse and ensure all employees know how to stop the belt in an emergency.

Inbelts Can Help with Conveyor Belt Efficiency

Proper planning and maintenance are crucial for achieving conveyor belt efficiency and longevity. Although pre-production planning and regular maintenance may seem inconvenient, they prevent production halts and downtime, ultimately leading to higher profits and reduced waste.

At Inbelts, we are committed to making your conveyor systems reliable, durable, and efficient. Our passion for the industry drives our innovative, high-quality products and services.

Leave Me Your Requirement!